Schnorr Disc Springs

DISC SPRINGS WITH TRAPEZOIDAL CROSS-SECTION

Disc Spring Engineering

Maximum load - minimum space - maximum flexibility

DISC SPRINGS WITH TRAPEZOIDAL CROSS-SECTION

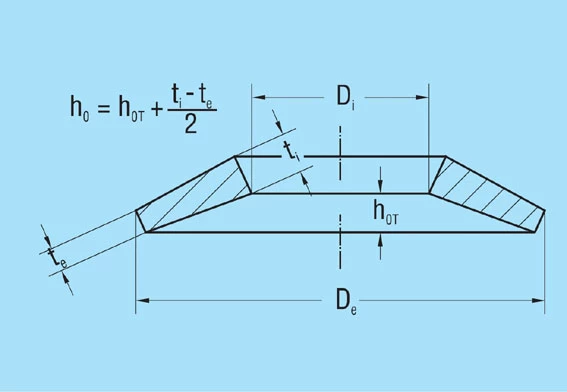

By the use of a trapezoidal cross-section it is possible to equalise the stresses on the spring upper and lower surfaces. The advantageous tensile stresses on the lower surface contribute to a better fatigue life. The equal compressive stresses at points ll and lll to give the optimum fatigue life can also be achieved with a rectangular cross-section spring if the ratios δ and ho/t are correctly chosen. In this regard therefore, the trapezoidal cross-section offers no advantages. Compared with a standard spring having a similar angle on the top surface, a trapezoidal spring will give less deflection. This can be increased by including intermediate rings, but these will also increase the overall stack length and require more space.

Figure 40 – click to enlarge

The main advantage of the trapezoidal cross-section disc spring is the ability to limit the stroke without additional parts. It is therefore possible to design a spring which is relatively fatigue free over the complete deflection range with relatively little increase in load towards the end of the stroke.

With the same installation space and under consideration of the permissible stresses, no more favourable spring data (more force or more deflection) can be achieved with disc springs with a trapezoidal cross-section than with springs with a square cross-section.

These few advantages and the higher manufacturing costs are the reasons why the trapezoidal disc spring is of no practical importance today.