Welcome to our thin section bearings, the ultimate destination for compactness and precision in your machinery. Thin section bearings are specially designed for applications where space constraints, minimal friction, and superior accuracy are paramount. Often integrated into the core of sophisticated equipment such as precision instrumentation, satellite systems, and robotics, these bearings play an essential role in maximising the efficiency and precision of these devices.

Thin section bearings are uniquely designed components that stand out due to their slim profile. Despite their slender build, they are critical in various machines and devices across numerous industries. They serve a specific function central to these machines’ efficiency and smooth operation. Their popularity is rising due to their distinct advantages, including space-saving properties and weight-reduction capabilities. However, like any other component, these bearings require proper maintenance and care to ensure their longevity and optimal performance.

Keep up to date with the latest product and technical information from IEC and its international supply partners.

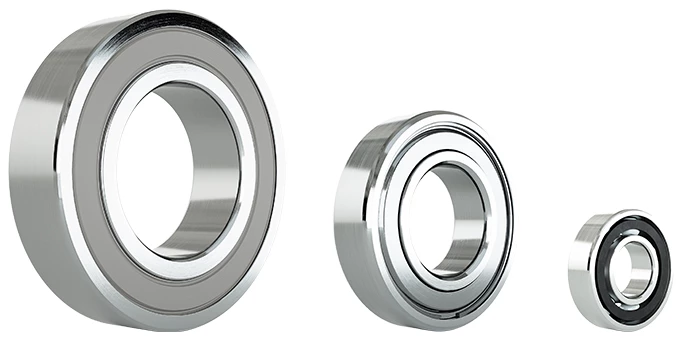

A complete range of bearings and configurations designed to carry load, reduce friction and support rotating and oscillating systems in any application.

You’ve got to appreciate the intricate design of these unique components, as understanding the engineering behind thin section bearings can give you a deeper sense of their crucial role in various machinery. Thin-section bearings are designed to handle radial and axial loads with high precision, even in restricted spaces, due to their slim cross-section. Unlike regular bearings, their slim design offers significant weight and space savings, which can optimise system performance. They are crafted from high-quality materials to ensure durability and efficient operation under extreme conditions. The design also carefully considers load capacity, speed, and life expectancy factors. Indeed, the complexity in the design and function of thin section bearings is a testament to the ingenuity of mechanical engineering.

With their compact design and reduced weight, Slim profile bearings are primarily utilised in applications where space constraints and weight reduction are critical factors. These bearings, also known as thin section bearings, are designed to offer high precision, high speed, and high load carrying capacity, while taking up minimal space. This makes them ideal for industries like aerospace and defence, industrial automation, and medical components where performance efficiency is paramount. They are also used in applications like HDD spindle motors, gyro stabilisers, and optical encoders. Their versatility and high performance make them a valuable tool in engineering. Despite their slim size, they demonstrate exceptional resistance to wear and tear, leading to increased product lifespan and reduced maintenance needs. Slim profile bearings provide a practical solution for demanding applications, combining strength and precision in a compact package.

In various industries, these components’ compact and lightweight design can make all the difference, allowing for more efficient and space-saving designs. Thin section bearings are used extensively in aerospace, where space and weight are crucial factors. They are integral to functioning satellites, spacecraft, and high-speed jets. They are found in advanced imaging equipment like MRI machines and CT scanners in the medical field, contributing to more precise diagnosis and treatment. The robotics industry also heavily relies on these bearings for their precision and compactness, enabling more intricate robotic movements. Furthermore, they are used in manufacturing certain types of machinery and equipment, where compactness and weight reduction significantly improve performance.

It’s no wonder these compact components are gaining more and more favour across various industries, given their significant advantages! Thin section bearings are gaining popularity due to their unique design, which allows for a lightweight, compact, and efficient bearing solution. This design minimises space usage, reduces weight, and increases overall system efficiency, leading to cost savings for manufacturers and improved performance for end users.

These ball bearings offer high precision and can handle high speeds and loads. They also facilitate easier and more flexible system designs. All these factors contribute to the increasing preference for thin section bearings in various applications, from aerospace and robotics to medical equipment and renewable energy systems.

We act as partners, making our customers’ engineering challenges ours to solve, removing stress and freeing up time to turn ideas in to innovation.

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Fey Laminar Seal Rings

Fuji Bearing Lock Nuts

Schnorr Load Washers

Fill out the form below, and our team will be in touch within 24 hours.