IEC and GRW: A Dynamic Partnership

The established partnership between IEC and GRW

As a trusted GRW bearings distributor, IEC’s enduring partnership with GRW is built on decades of collaboration, mutual trust, and a shared dedication to quality. Over the years, this relationship has enabled us to bring exceptional precision-engineered solutions to the market. By working closely together, IEC and GRW continue to innovate and refine offerings, ensuring that we meet the evolving needs of our customers.

History and excellence of GRW ball bearings

The benefits of their products include:

- Unmatched Precision: GRW ball bearings are crafted with unparalleled precision, delivering optimal performance in even the most exacting applications.

- Exceptional Reliability: Designed for durability, GRW bearings are known for their consistent performance in vital machinery across various sectors.

- Bespoke Solutions: GRW excels in delivering tailored solutions, collaborating closely with customers to meet their precise needs and unique challenges.

Choose IEC as your trusted source for GRW products

IEC is the UK sales and applications office GRW aerospace and defence applications. Through our connections and experience we bridge the gap between product and project, improving the availability of specialist components in critical applications. Count on IEC for expert guidance, bespoke solutions, and exceptional service when sourcing GRW products.

We have a range of GRW bearings to suit the most complex of applications, and the most sensitive of budgets.

- ABEC-1 through ABEC-9

- Range of standard configurations

- Carbon chrome & exotics

- Full customisation

- Specialist coatings & lubricants

- From stock or built to order

- Exceptional Accuracy: Crafted to ISO P4A or ABEC 9 standards for precise operation.

- Versatile Configurations: Available in plain and flanged designs, with options for shields or seals.

- Corrosion Resistance: Made with exclusive SV material for superior corrosion resistance and longevity.

- High-Speed Performance: Suitable for high-speed applications, including hybrid bearings with ceramic balls and spindle bearings.

- Custom Solutions: GRW offers tailored ball bearing assemblies to meet specific application needs.

- Reliability: Manufactured by an ISO 9001:2008 certified company, ensuring high quality and dependable performance.

Explore our GRW applications

Explore our range of GRW products

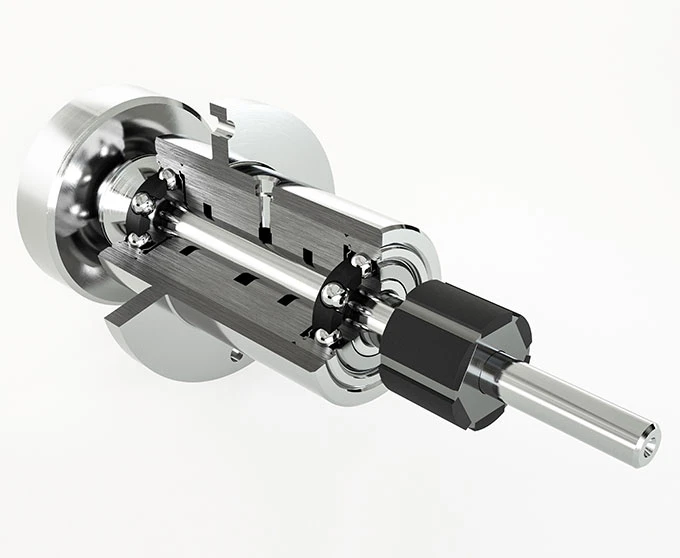

Axial bearing

Radial deep groove

Spindle

Duplex Bearing

Duplex bearings are available in different configurations, such as back-to-back, face-to-face, tandem, and universal.