You’re designing a high-precision electric motor, a robotic arm, or a compact gearbox. Everything is engineered down to the last micron. The bearings are installed, the shafts are aligned — and then you hear it.

A faint hum. A vibration. A subtle play in the shaft that wasn’t there before.

This isn’t just an annoyance. Over time, axial play can damage bearing races, generate unwanted heat, and lead to premature failure. The cause? Thermal expansion, manufacturing tolerances, and dynamic loading — all shifting the preload on your bearings.

That’s exactly the problem IEC helped a European automation customer solve — with Schnorr K Springs, precision-manufactured in Germany.

The Challenge: Preload vs Reality

Axial preload in bearings is essential for:

Reducing noise

Eliminating play

Preventing skidding and vibration

Maximising bearing life

But achieving the perfect preload is complicated. Even small variations in temperature or part tolerances can shift the axial load.

Common challenges include:

Shaft growth at high speeds

Housing expansion due to heat

Tolerance stack-ups in assemblies

Axial movement under dynamic load

And unlike many components, bearings often don’t offer second chances. A small preload loss today can lead to catastrophic failure tomorrow.

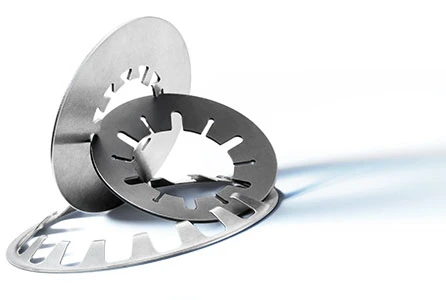

The Solution: K Springs — Small, Flexible, Reliable

Schnorr’s K Springs, distributed by IEC in the UK, are specifically designed to maintain consistent bearing preload even as assembly dimensions shift.

Key features:

Fits directly into bearing bores (internal diameter matched to ball bearing sizes)

Can preload inner or outer rings

Stackable for adjustable preload

Available in slotted and non-slotted designs

Compensates for thermal expansion and tolerance variations without losing preload

Why it works:

Axial flexibility absorbs expansion without significant force variation

Prevents bearing play across the full temperature and load range

Simplifies design — no complicated shimming or constant readjustments

Real-World Applications

Electric Vehicle Traction Motors

An EV manufacturer was experiencing noise issues at high RPM due to shaft growth under heat. By integrating K Springs, they maintained stable preload on motor bearings across wide temperature swings, eliminating NVH (noise, vibration, harshness) issues.

Industrial Robotics

A robotics OEM used K Springs to maintain bearing stability in high-speed pick-and-place arms. Without them, rapid cycling caused preload loss and positional inaccuracies. K Springs absorbed dimensional changes while preserving precision.

Precision Gearboxes

In a high-speed gearbox design, stacked K Springs were used to absorb expansion and ensure continuous preload across varying operating temperatures — critical for maintaining gear mesh accuracy under full load.

The Result: Silence, Stability, and Service Life

Thanks to their precision engineering, Schnorr K Springs quietly solve one of the most frustrating challenges in bearing assemblies — keeping preload stable, even when everything else moves.

With IEC’s engineering support and Schnorr’s German-made quality, design teams across Europe have a simple, reliable solution for complex bearing assemblies.

Partner with the Experts: IEC

As the official UK distributor for Schnorr Components, IEC helps manufacturers, OEMs and designers select the right K Spring solution for their specific application.

📩 Contact us today

🌐 iecltd.co.uk/brands/schnorr