In high-speed machinery, precision isn’t optional. Even tiny amounts of axial play in ball bearings can lead to unwanted noise, vibration, and wear. And when thermal expansion comes into play, keeping preload consistent becomes even harder.

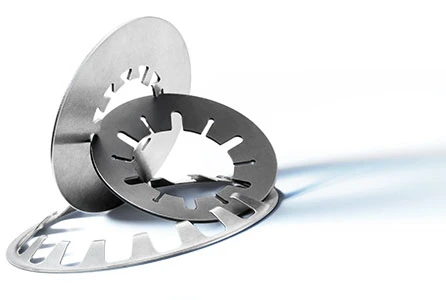

That’s where K Springs from Schnorr Washers— made in Germany and distributed in the UK by IEC — make the difference.

The Challenge: Managing Preload in a Changing World

Bearings aren’t static. Heat, load changes, and manufacturing tolerances all introduce variations in assembly length. Without a way to accommodate these shifts, preload can fluctuate, leading to:

- Noise (bearing chatter)

- Axial play

- Reduced bearing life

- Increased wear

In some applications, even microns of movement can affect performance — especially in:

- Electric motors

- Gearboxes

- Machine tools

- Automotive systems

- Robotics

The Solution: K Springs — Simple, Flexible, Effective

K Springs are designed to apply consistent axial preload on ball bearings, even when the assembly length changes due to heat or tolerances. Their slotted design allows controlled flexibility while maintaining force.

How it works:

- K Springs fit directly into standard bearing bores.

- One size can work across multiple bearing models — e.g., a spring for a 6302 bearing’s outer ring can also preload the inner rings of 6205 and 6305.

- They can be stacked to adjust preload depending on design needs.

- Both slotted and non-slotted versions are available depending on the application’s dynamics.

Key Benefits:

- Reduces bearing noise and vibration

- Eliminates axial play

- Absorbs thermal expansion without significant preload variation

- Simplifies assembly — no complex adjustment needed

Real-World Examples

- Electric Motor Manufacturer

A motor OEM used K Springs to eliminate axial play in a compact fan motor, reducing noise complaints in the field by 40% and extending bearing life. - Robotics Assembly

A robotics customer used multiple stacked K Springs to maintain consistent preload across varying shaft temperatures, ensuring precision positioning even under dynamic load conditions.

The Result: Quiet Bearings, Longer Life, Less Downtime

In many cases, K Springs are installed once — and quietly do their job for years without attention. They are a simple solution to a complex problem, keeping bearings tight, smooth, and quiet across industries.

Partner with IEC

As the official UK distributor for Schnorr Components, IEC supplies K Springs and other precision disc springs across a wide range of industries.

Contact us to discuss your bearing preload application info@iecltd.co.uk