Special Ball Bearings: Custom Solutions for Demanding Applications

GRW Special Bearing Solutions For Challenging Environments

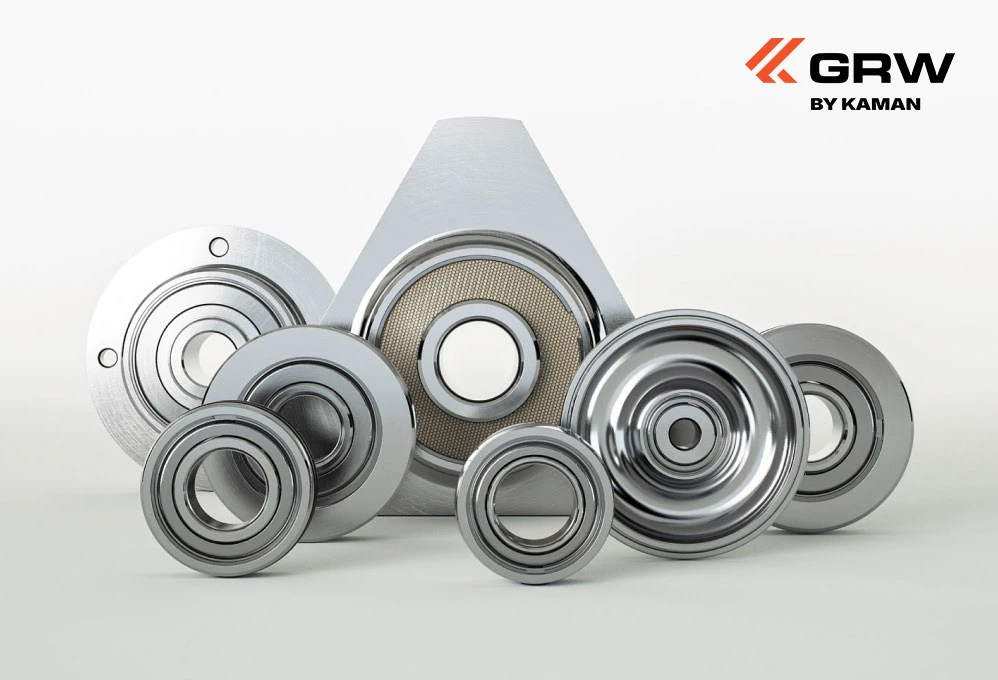

Looking for a customised solution to meet your specific ball bearing needs in challenging environments? At IEC, we offer a wide range of special bearing types, developed by GRW, to meet any requirement. GRW designs and develops these ball bearings, which are customised to your specifications.

Design and Dimensions to Meet Your Needs

IEC offers customised ball bearing solutions to fit your exact requirements. Whether you need miniature bearings or standard-sized products capable of handling extreme conditions like heat, cold, or harsh chemicals, GRW bearings can provide the perfect fit. We work with you to identify the most suitable bearing type and customise it to meet your application needs. From specialised miniature bearings to robust standard options, we deliver high-quality solutions that perform under demanding conditions.

AT IEC, We Provide You With The Following Options:

Need a customised solution for your ball bearing application? IEC provides a variety of specialised bearing types for challenging environments. Our bearings are specifically selected and customised by GRW to fit your unique requirements.

- Super duplex bearings

- Extra duplex bearings

- Tandem duplex bearings

- Ball bearings with integrated shaft

- Ball bearings with altered outer geometry

- Ball bearings with sealed housing

- Rotation-symmetrical high-precision machined parts

GRW Bearings Product Range

GRW extensive range includes various bearing types and configurations designed to carry loads, reduce friction, and support rotating and oscillating systems across multiple applications.

Benefits of Special Ball Bearings

Special ball bearings offer unique advantages compared to standard bearings. Integrating peripheral components, like oil seals or bearing washers, into the outer ring simplifies assembly and saves time. Additionally, the two-row ball-bearing design allows for higher load-carrying capacity and increased stability, making it ideal for heavy-duty applications. High-performance materials, including corrosion-resistant plastics, further enhance durability and reduce friction. These features make special ball bearings well-suited for demanding conditions, providing increased reliability and efficiency.

Types Of Special Bearings

Special ball bearings are engineered for unique and demanding applications. These bearings often deviate from standard dimensions to accommodate specific requirements, offering enhanced features like integrated components, multi-row designs, and specialised materials.

- Integrated Bearings: Include peripheral components such as oil seals to simplify the assembly process and reduce the need for separate parts.

- Two-Row Bearings: Feature two rows of balls for increased load capacity and stability compared to single-row bearings.

- Plastic Bearings: Made with corrosion-resistant materials and additives to reduce friction and weight, ensuring optimal performance in tough conditions.

These variations make special ball bearings versatile and well-suited for a wide range of industrial needs.

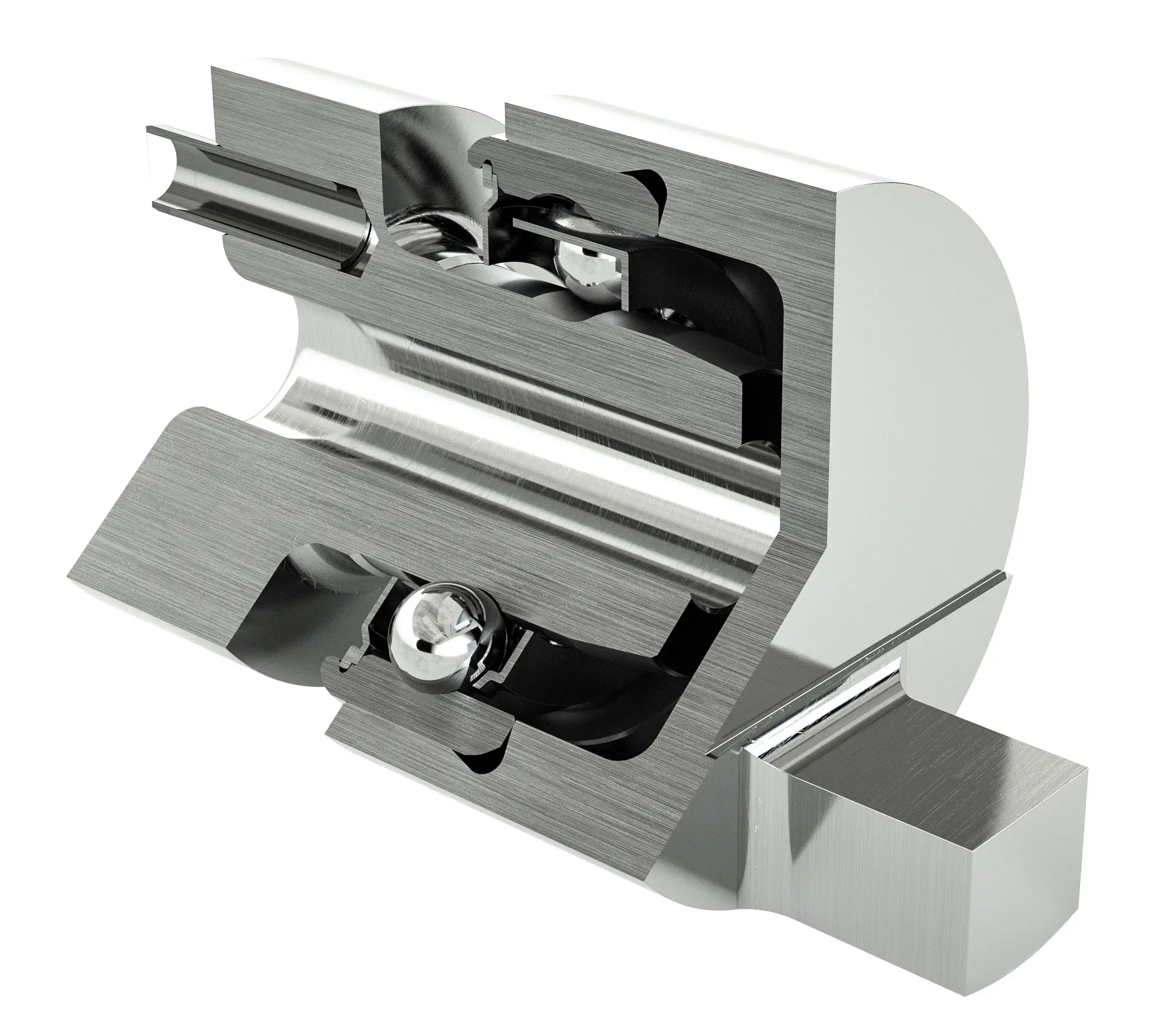

Angular Contact Ball Bearings

Angular contact ball bearings are designed to handle both radial and axial loads, thanks to their unique contact angle between balls and raceways. This allows them to support high combined loads with excellent axial rigidity, making them ideal for high-precision, high-speed applications such as machine tools, automotive components, and robotics. Their ability to manage combined forces ensures increased flexibility and reliable performance in demanding environments.

Pros & Cons of Using Angular Contact Ball Bearings

Angular contact ball bearings offer several advantages in industrial applications. First, they can handle radial and axial loads, making them versatile for various equipment. This helps reduce the need for multiple bearing types, simplifying inventory management. Second, their design allows for high-speed operation, making them suitable for applications that require quick rotation. Third, angular contact ball bearings have a contact angle, which distributes the load evenly across the balls and raceways, increasing their load-carrying capacity and overall durability.

Single-Row Deep Groove Ball Bearings

These bearings have a row of balls positioned at an oblique angle to the raceway. They are designed to accommodate both radial and axial loads in one direction. Single-row deep groove ball bearings are commonly used in electric motors, pumps, and gearboxes.

Double-Row Deep Groove Ball Bearings

As the name suggests, these bearings have two rows of balls positioned at an angle to the raceway. They can withstand higher radial loads and accommodate axial loads in both directions. Double-row deep groove ball bearings are often used in agricultural equipment, machine tools, and printing presses.

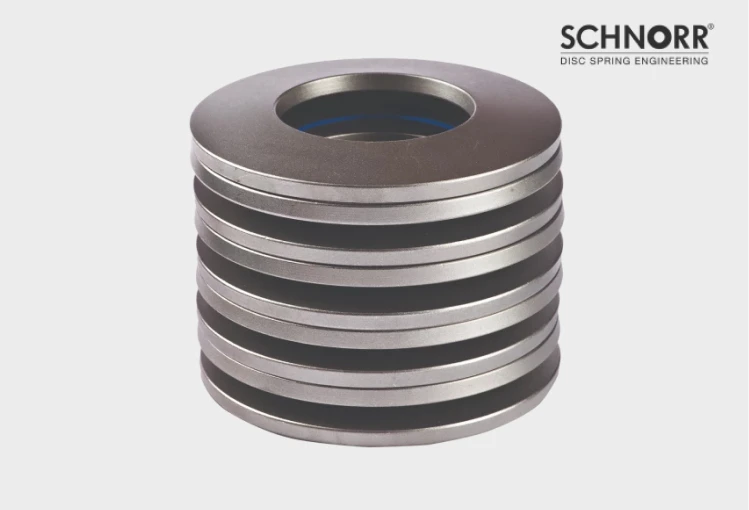

Extra Duplex Bearings

Extra duplex bearings are designed to handle heavy radial and axial loads. They consist of two sets of angular contact ball bearings arranged in a back-to-back or face-to-face configuration. These bearings are commonly used in construction equipment, mining machinery, and heavy-duty applications.

Deep Groove Ball Bearings

Deep groove ball bearings are versatile and widely used across industries. Characterised by deep raceway grooves, they can carry both radial and axial loads. Their simple design ensures high reliability, making them ideal for power transmission equipment, motors, pumps, and automotive applications. Known for high-speed operation, low friction, and low noise, they come in various sizes and configurations, making them suitable for numerous applications.

Common Applications for Deep Groove Ball Bearings

Deep groove ball bearings are versatile and used across many industries due to their self-retaining design and resistance to high loads. Common applications include power transmission, electric motors, pumps, gearboxes, and agricultural machinery. Available in single-row and double-row designs, they handle radial and some axial loads, with sealed and unsealed options for contamination protection. Their low frictional torque allows high-speed operation, making them ideal for machine tools and automotive components. Overall, deep groove ball bearings are reliable and suitable for both radial and axial load-bearing needs.

Pro And Cons of Using Deep Groove Ball Bearings

Deep groove ball bearings are popular due to their versatility, handling both radial and axial loads across various applications. They can operate in challenging environments, including those with contamination or difficult lubrication. With high resistance to wear, they withstand heavy loads and high speeds, requiring minimal maintenance. However, they have limited capacity for predominantly radial loads and often need additional fittings for proper alignment. Despite these limitations, their versatility, durability, and low maintenance make them a reliable and cost-effective choice for many industries.

Explore Our Product Range

Case Studies

We act as partners, making our customers’ engineering challenges ours to solve, removing stress and freeing up time to turn ideas in to innovation.

Product:

Application:

Challenge:

Solution:

Product:

Application:

Challenge:

Solution:

Product:

Application:

Challenge:

Solution:

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.