Groundbreaking Innovations in the World of Ball Bearings: New Products from GRW

IEC has built its reputation in aerospace engineering by providing top-quality aerospace and aviation components, paired with expert-led support that consistently goes beyond customer expectations.

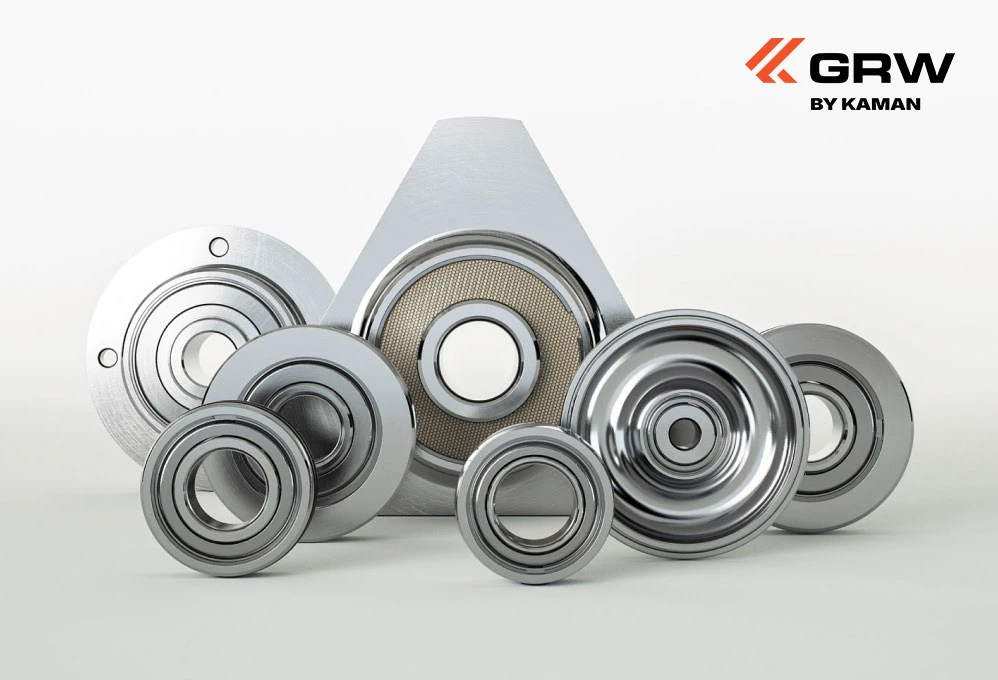

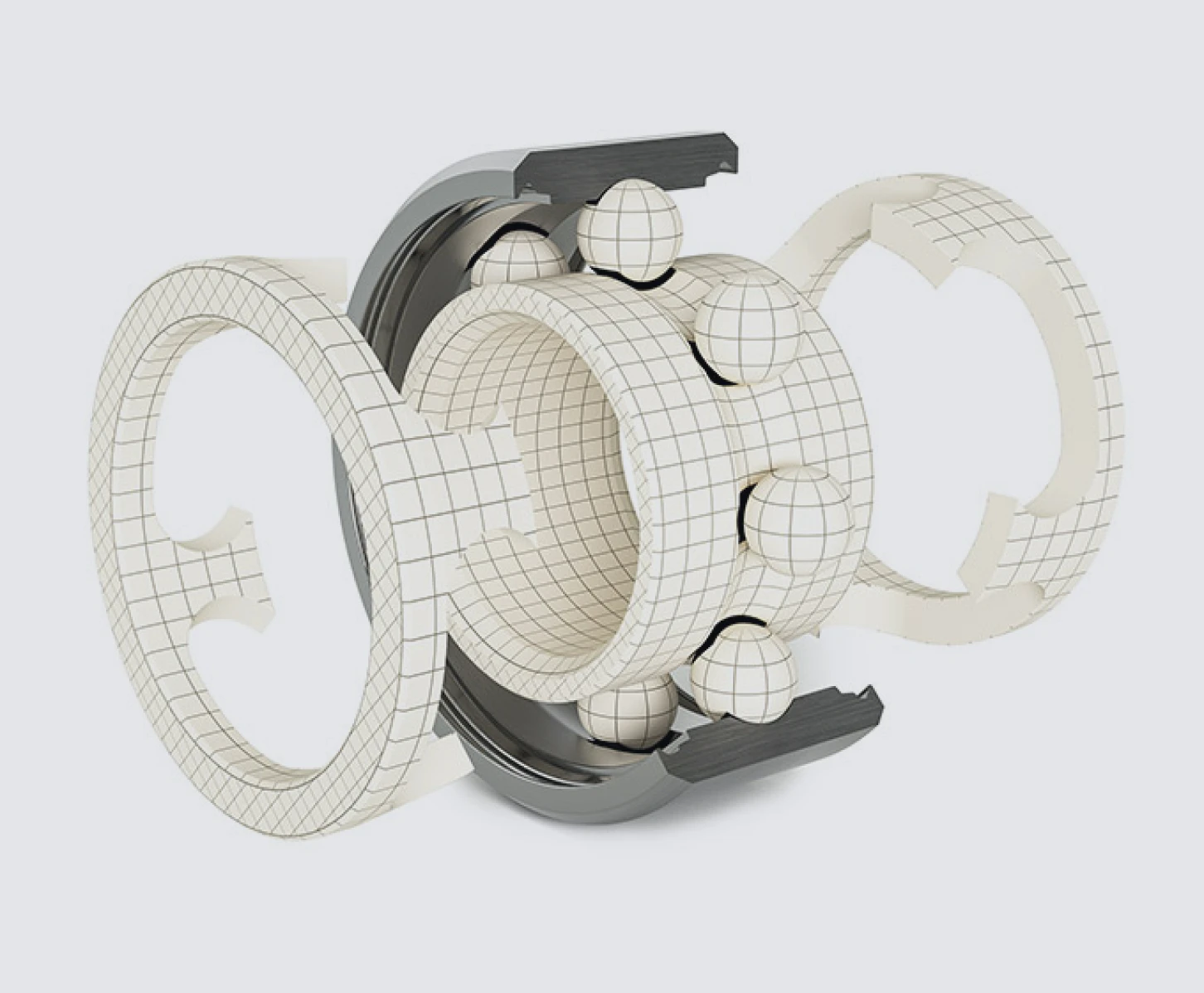

Benefit from High Performance Q21 Ball Bearings

Instruments like dental handpieces demand the highest standards from their ball bearings. These bearings must endure high rotational speeds while remaining incredibly resilient. Additionally, they need to operate as quietly as possible to ensure a comfortable experience for patients. GRW’s new Q21 ball bearings, crafted with advanced materials and innovative designs, deliver exceptional performance even in challenging conditions. The range includes Q21irac®, Q21speed®, and Q21twin®.

Q21IRAC : Advanced Deep Groove Ball Bearings for Extended Lifespan

Tilting conditions can cause standard deep groove ball bearings to face extreme forces, leading to early failure. GRW’s innovative Q21IRAC® features address this issue by maintaining optimal performance, even when the rotor shaft or rings are tilted. The Q21irac® deep groove ball bearings guide the ball set along a near-elliptical path, mimicking the movement of a perfectly aligned bearing. This design ensures quieter operation and significantly reduces early wear, resulting in a much longer lifespan compared to conventional radial deep groove ball bearings.

GRW XTRA Material: Ball Bearings Designed for Extreme Conditions

In demanding environments such as the human body, desert sands, Mars, or the freezing vacuum of space, GRW ball bearings and units perform flawlessly under extreme conditions. Whether facing harsh temperatures in high-speed jet engines or aggressive processing applications, GRW’s specially developed XTRA materials equip these bearings to withstand even the toughest challenges.

Q21SPEED: Innovative Design for Enhanced Performance

GRW has developed the Q21speed® feature specifically for deep groove ball bearings used in high-speed applications. This new retaining cage design significantly improves running friction and dynamic performance. Additionally, the patented ball-bag design increases lifespan and ensures quiet operation. The innovative Q21speed® feature can be applied to both snap cages in radial deep groove ball bearings and window cages in angular contact ball bearings, delivering superior performance across various applications.

Q21TWIN: Patented Cage Design for Reduced Wear and Extended Lifespan

XTRALUBE: Advanced Lubrication for High-Speed Applications

Explore our product range

Unlock XTRA Performance Benefits

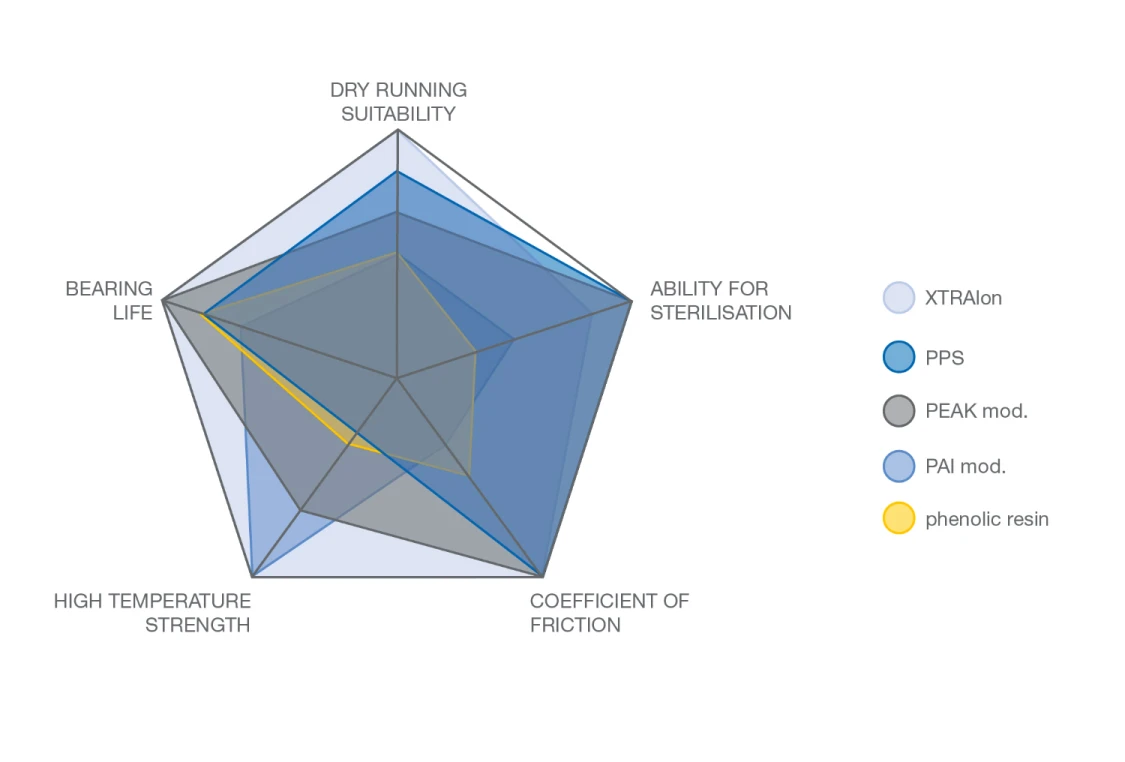

XTRAIon – Patented Cage Material

Designed for high-performance applications, GRW’s XTRAIon is a premium material developed using unique manufacturing methods. This innovative XTRA-material features a dry lubrication chemically bonded to the base polymer polyamidimide (PAI), creating a homogeneous structure with minimal surface contact during autoclaving. The result is a range of key benefits:

- Exceptional tolerance to high temperatures

- Reduced friction and wear

- Extended lifespan of the application

GRW Future Innovations: A Glimpse Ahead

GRW’s research and development team is continually focused on the future, advancing their material portfolio for bearing rings, cages, lubricants, and coatings. They are also exploring innovative production technologies to enhance these components. The XTRA series remains a key focus, with plans to expand and refine this cutting-edge range as part of GRW’s ongoing commitment to innovation and performance.

GRW's Goal: Continuously Raising the Bar for Performance

The focus of GRW’s future projects is on achieving the highest possible performance across applications. GRW is constantly pushing the performance limit upwards, driven by truly innovative ideas and new technologies.

New design concepts and bearing innovations are a priority, ensuring that GRW’s roller bearings and bearing units are perfectly adapted to each individual application. This commitment allows GRW to provide significant advantages in system construction, offering unparalleled reliability and efficiency.

Preparing GRW Products for the Future

- System design

- Logistics

- Testing

- Simulation

- Field application

This approach ensures that GRW solutions seamlessly align with your digital world and workflows, providing optimal performance and efficiency.

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.