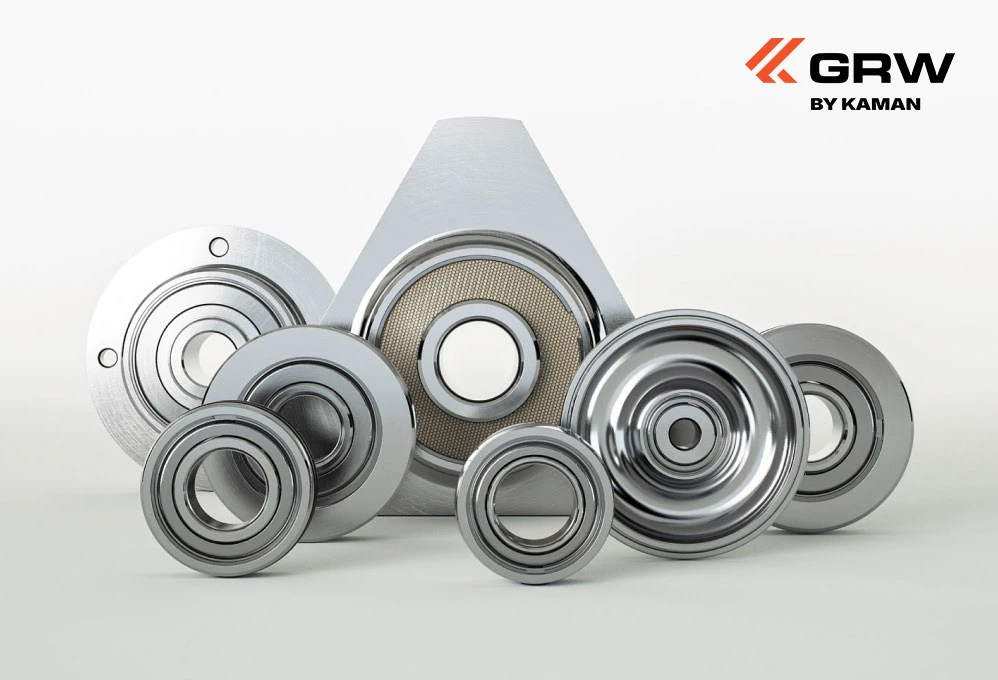

Highly Modern Ball Bearings for Aviation and Space by GRW

IEC is proud to be the nominated UK partner for GRW aerospace and defence applications, ensuring that GRW’s advanced ball bearing solutions are available to meet the demanding requirements of these sectors. GRW’s precision-engineered ball bearings are utilised in a diverse range of technologies, providing exceptional performance under extreme mechanical, thermal, and environmental conditions.

Advanced Ball Bearings for Aviation and Space

Satellites, aircraft, and precision instruments all depend on technologies that are meticulously designed to operate reliably under high thermal and mechanical stress. GRW’s aerospace-grade ball bearings are engineered to withstand the extreme conditions of high altitudes and outer space, ensuring reliability, low frictional torque, and precise load handling capabilities critical for mission success.

Versatile Ball Bearings for Ground and High-Altitude Applications

GRW ball bearings are integral to numerous systems within the aviation and aerospace sectors, offering high fatigue resistance, precise load distribution, and the ability to function in harsh environments. These applications include:

- Satellite switching components

- Measuring and control systems

- Fuel supply mechanisms

- Air circulation systems

- Air conditioning systems

- Antenna and sunshield systems

- Cargo handling systems

- Electronically powered control units for engines

- Supply stations

- Pressure regulation units

- Navigation instruments

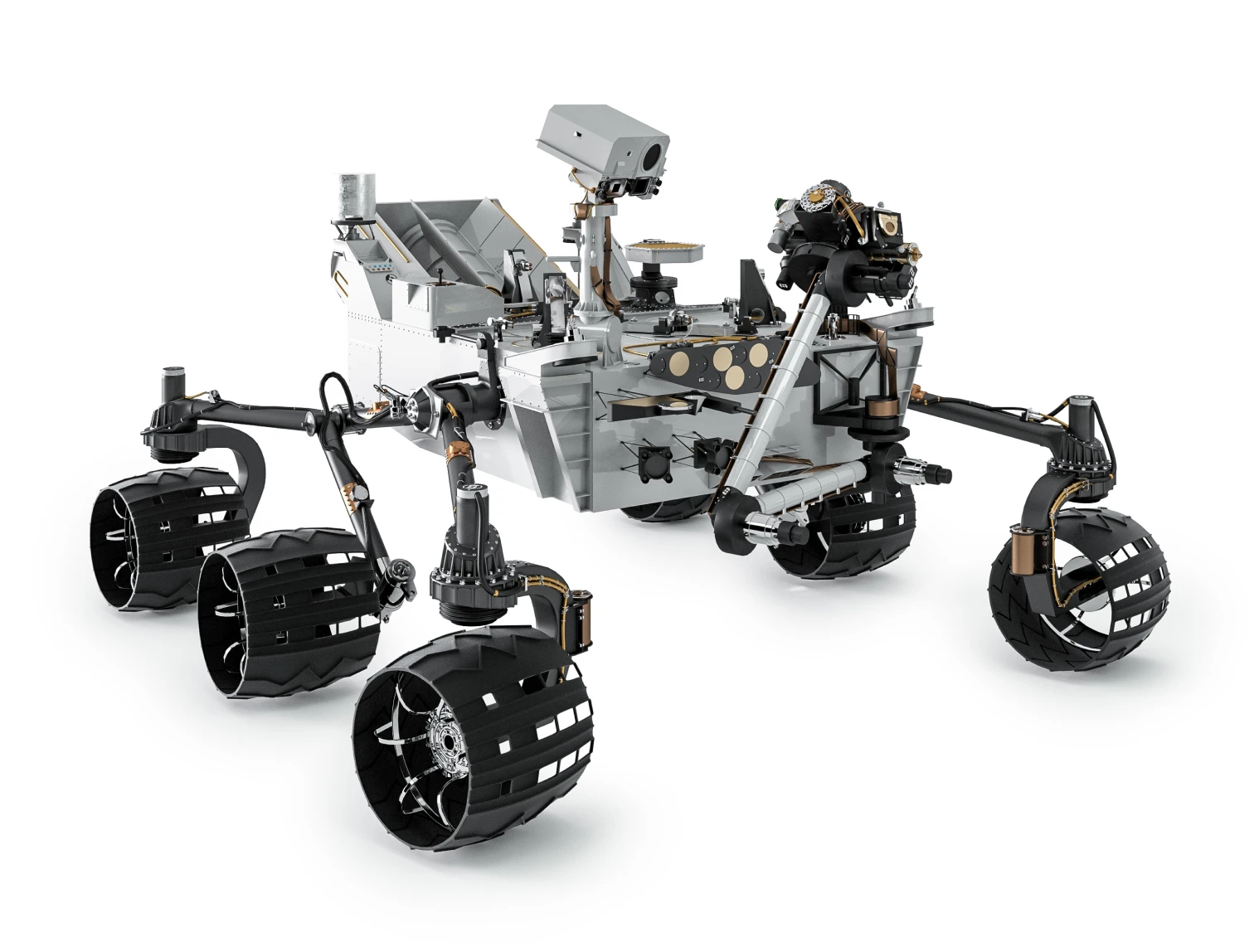

Innovative Ball Bearing Solutions with a Proven Track Record

GRW’s bearings have played a key role in significant aerospace missions, including the NASA Mars expeditions in 1997, 2003, and 2020. For these critical missions, structural stability and precise operational control are non-negotiable, starting from the manufacturing and quality assurance stages. By choosing GRW’s ball bearings, you benefit from high-grade engineering and the following advantages: When you choose GRW’s ball bearings, you gain access to a range of benefits, including:

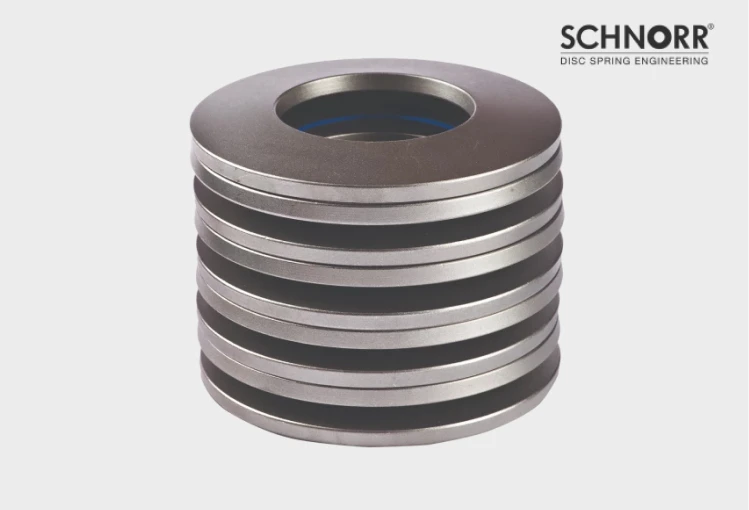

- Over 300 lubrication options, including MIL-spec lubricants, capable of operating in temperature extremes ranging from -270°C (-454°F) to +450°C (+842°F), ensuring stability and minimal wear in diverse environmental conditions

- Vacuum-compatible lubricants with low outgassing properties, specifically designed to maintain optimal bearing performance in high-vacuum environments, such as space

- A variety of dry lubricants and specialised coatings

- Rigorous quality control using advanced noise and vibration analysis to ensure low operational disturbances and to meet aerospace-level precision standards

- Documentation of preload, where needed, using the "broken-curve method"

- Ongoing development and evaluation of materials and testing methodologies to ensure bearings meet evolving aerospace requirements and achieve superior reliability

Explore our product range

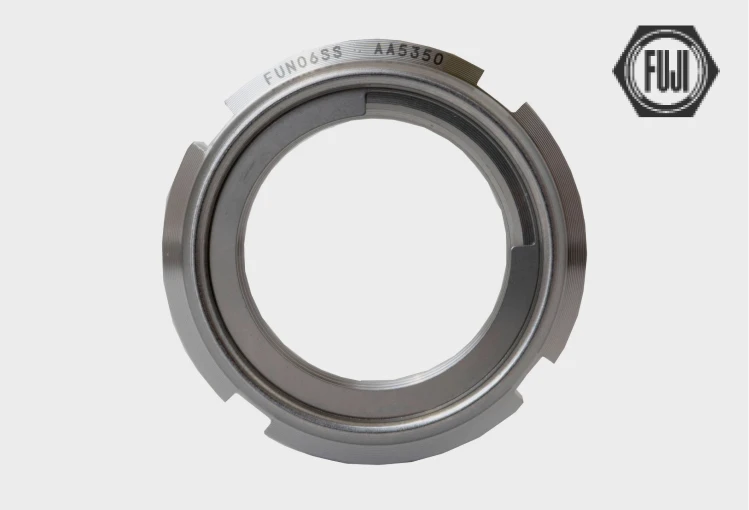

Maximise Performance with Custom High-Precision Ball Bearings

GRW precision-engineered ball bearings are designed to meet and exceed strict safety and quality standards in the defence sector. GRW ensures flawless performance through meticulous development, manufacturing, and rigorous testing. Built to withstand extreme environments, our corrosion-resistant ball bearings excel in demanding conditions, from harsh deserts to turbulent seas. Tailored for the defence industry, our bearings offer durability and reliability in every mission. Partner with our aerospace and defence experts to create custom solutions that align with your specific requirements and uncompromising quality standards.

GRW Products Deliver Protection and Reliability

Discover the diverse applications of GRW ball bearings in the defence industry, trusted for their precision and durability:

- Image processing systems

- Rocket equipment and aircraft

- Electric drive systems

- Actuators

- Night-vision devices

- Optical instruments

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.