GRW High Precision Ball Bearings

Elastic behaviour of deep groove ball bearings

High precision ball bearings in grades up to ABEC 9 with bores from 1 to 30mm and comparable inch dimensions

General Information

ELASTIC BEHAVIOUR OF DEEP GROVE BALL BEARING

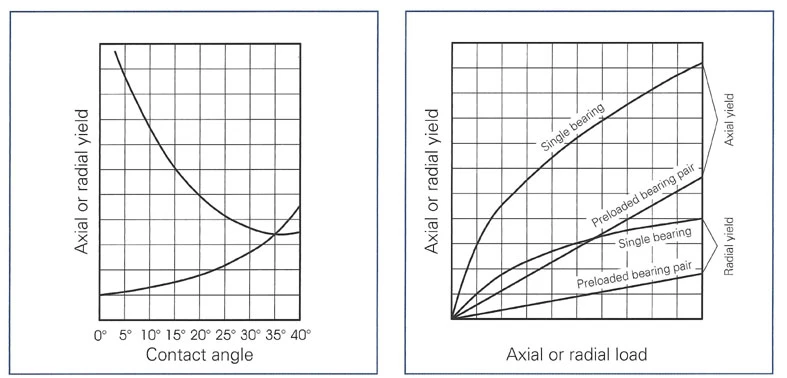

Two types of elastic yield should be distinguished with ball bearings: axial and radial yield.

Axial elastic yield

The axial elastic yield of a ball bearing is the distance which the inner ring moves axially compared with the outer ring when the axial clearance of the bearing has been removed, and the bearing is axially loaded. It does not increase linearly with the applied load as the contact areas between balls and raceways become larger with increasing load.

Radial elastic yield

The radial elastic yield is caused by a radial force component after radial play has been removed. Given similar conditions, with small contact angles the radial yield is considerably less than the axial yield. With increasing contact angle, the radial yield increases while the axial yield decreases, up to a contact angle of approx.. 35o, when values become practically the same.

Both types of yield depend on the internal construction of the bearing, the radial clearance and applied load.

The relatively large amount of yield can be reduced by using preloaded bearing pairs (see ‘Duplex Bearings’). Preloading will result not only in a reduction of the elastic yield, resulting in increased rigidity, but also in a near to linear relationship between loading and yield for a considerably wide range of applied load. For instance, a ball bearing pair with 10N preload will maintain linearity up to approx. 30N external axial load.

To estimate this, the following formula can be used:

Fv = Fa / 3

Fv = axial preload [N]

Fa = axial bearing loading [N]

Please contact us for further information.