Fuji Bearing Lock Nuts

Designed to locate, secure, and pre‑load bearings and shaft components with precision, our Fuji bearing lock nuts and bearing locknuts simplify assembly and reduce total cost of ownership.

Quality, Secure Bearing Locking Nut Solutions

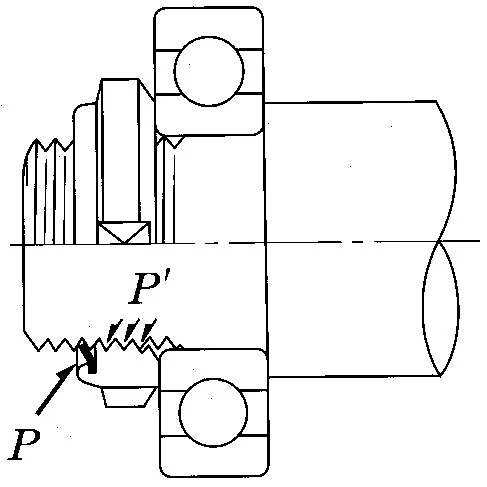

Fuji bearing lock nuts are engineered for high-performance shaft fastening and bearing positioning, eliminating the need for machined keyways, tab washers, or multiple components. The one-piece Fuji locknut features a self-locking spring-peened friction ring that applies prevailing torque (via force P and reaction P’) to provide secure bearing retention, locking bearings – or gears and pulleys – firmly on the shaft.

Available in carbon, high-carbon, and stainless steel, these precision-machined bearing lock nuts are manufactured with ISO metric threads and stocked in sizes M10 to M150 (IEC holds inventory M10–M100), with socket tools up to M50 readily available for efficient bearing installation and servicing.

Fuji bearing lock nuts are versatile shaft-locking solutions used across a range of industrial sectors where secure, vibration-resistant fastening is critical. They are widely adopted in industrial machinery applications – from precision automated assemblies to heavy duty rotating equipment – and are particularly suited to automotive manufacturing, industrial production lines, power generation, material handling equipment, and machine tool assemblies where maintaining shaft integrity and reducing rotational imbalance are key performance factors. For specialised needs, Fuji lock nuts also support applications in defence and aerospace assembly systems where reliable component retention under dynamic loads is essential.

- Slim design & simplified bearing installation – no keyway machining or tab washers required

- Re-usable, self-locking action – retains prevailing torque for up to 100 installs

- Wide size range for shaft retention – standard M10 to M150, tools available up to M50

- Improved shaft balance & integrity – reduces vibration, shock, and rotational imbalance in rotating machinery

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Markets

Case Studies

We act as partners, making our customers’ engineering challenges ours to solve, removing stress and freeing up time to turn ideas in to innovation.

Product:

Application:

Challenge:

Solution:

Product:

Application:

Challenge:

Solution:

Product:

Application:

Challenge:

Solution:

Fuji Bearing Locknuts Catalogue

FUJI BEARING LOCKNUTS

The Fuji Fine-U-Nut was developed to simplify the assembly and reduce costs involved in securing ball bearings.

The manufacturer has more than 30 years experience in locknut technology and their factory is ISO 9001 approved.

Construction & Function

The Fuji Bearing Locknut is a one piece item where the locking function is performed by a spring peened into the top of the nut. In use the spring bears on the flank of the shaft thread with force (P) generating reaction force (P’) in the screw threads with a resulting high friction torque (prevailing torque). The nut therefore remains locked in position.

Fuji Bearing Locknuts are manufactured in carbon, high carbon and stainless steel and are a stock item at IEC in sizes from M10 to M100.

KEY BENEFITS

- Unique slim body design

- Secure locking without keyway and tab washer

- Improved shaft strength and balance

- Simple infinite adjustment

- Re-usable up to 100 times

- Sizes from M10 to M150

- Carbon, high carbon and stainless steel versions

- Resists vibration and shock

- Equally effective for rotation in either direction even with rapid reversals

- One piece construction reduces stock and allows simpler, quicker assembly

PROOF LOAD & MAXIMUM TIGHTENING TORQUE

| Part No | SS (Low Carbon Steel) | SC (High Carbon Steel) | SUS (Stainless Steel) | ||||

| Prevailing Torque (Nm) | Proof Load (N) | Max Tightening Torque (Nm) | Proof Load (N) | Max Tightening Torque (Nm) | Proof Load (N) | Max Tightening Torque (Nm) | |

| FU00 | 1.4 | 9500 | 13.3 | 12860 | 17.6 | 7710 | 8.9 |

| FU01 | 2.2 | 11080 | 18.9 | 15000 | 24.8 | 9000 | 12.7 |

| FU02 | 3.1 | 17810 | 36.7 | 24120 | 48.6 | 14470 | 24.3 |

| FU03 | 3.7 | 20180 | 46.9 | 27330 | 62.2 | 16400 | 31.0 |

| FU04 | 4.7 | 29020 | 77.8 | 39300 | 103.7 | 23580 | 50.9 |

| FU05 | 9.8 | 41160 | 139.4 | 55740 | 185.3 | 33440 | 91.7 |

| FU06 | 12.7 | 49400 | 199.4 | 66890 | 265.5 | 40130 | 130.6 |

| FU07 | 16.2 | 66500 | 309.4 | 90050 | 413.3 | 54030 | 201.5 |

| FU08 | 19.6 | 87080 | 458.4 | 117920 | 613.9 | 70750 | 296.9 |

| FU09 | 23.5 | 109720 | 645.6 | 148580 | 865.9 | 89150 | 416.6 |

| FU10 | 29.4 | 134580 | 877.2 | 182250 | 1177.5 | 109350 | 565.2 |

| FU11 | 35.3 | 145140 | 1041.1 | 196540 | 1397.3 | 117920 | 670.8 |

| FU12 | 41.2 | 158330 | 1238.1 | 214410 | 1662.1 | 128640 | 797.6 |

| FU13 | 50.0 | 188680 | 1595.2 | 255500 | 2142.5 | 153300 | 1026.5 |

| FU14 | 54.9 | 203190 | 1847.0 | 275160 | 2481.8 | 165090 | 1187.4 |

| FU15 | 66.6 | 237500 | 2310.9 | 321620 | 3105.9 | 192970 | 1484.9 |

| FU16 | 70.6 | 295560 | 3049.8 | 400230 | 4104.9 | 240140 | 1953.2 |

| FU17 | 76.4 | 336460 | 3679.8 | 455620 | 4956.0 | 273370 | 2353.5 |

| FU18 | 83.3 | 356250 | 4123.1 | 482430 | 5554.0 | 289450 | 2636.2 |

| FU19 | 88.2 | 401110 | 4889.4 | 543180 | 6590.0 | 325900 | 3122.3 |

| FU20 | 96.0 | 448610 | 5748.4 | 607500 | 7750.5 | 364500 | 3668.1 |

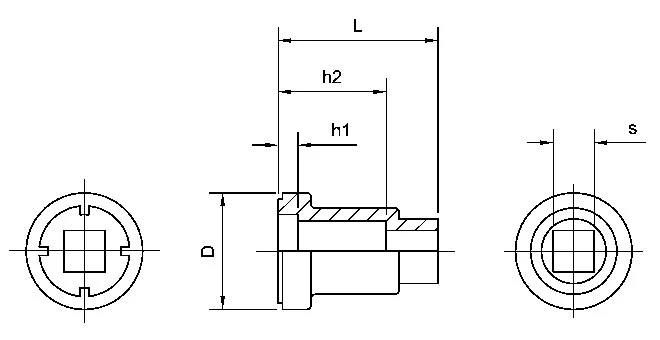

SOCKET TOOLS FOR BEARING LOCKNUTS

Sizes available up to M50.

Quotations/dimensions for larger sockets can be supplied on request.

| Order Ref | Nut | D | L | h1 | h2 | s |

| FU00 | M10x0.75 | 23 | 36 | 4.4 | 24 | 9.52 (3.8″) |

| FU01 | M12x1.0 | 27 | 37 | 4.6 | 25 | |

| FU02 | M15x1.0 | 31 | 38 | 5.7 | 26 | |

| FU03 | M17x1.0 | 34 | 39 | 5.8 | 27 | |

| FU04 | M20x1.0 | 38.5 | 40 | 6.9 | 28 | |

| FU05 | M25x1.5 | 45.5 | 46.5 | 8.1 | 30.5 | 12.7 (1/2″) |

| FU06 | M30x1.5 | 53 | 50 | 8.1 | 34 | |

| FU07 | M35x1.5 | 60.5 | 53.5 | 9.2 | 37.5 | |

| FU08 | M40x1.5 | 67 | 57 | 10.2 | 41 | |

| FU09 | M45x1.5 | 74.5 | 60.5 | 11.2 | 44.5 | |

| FU10 | M50x1.5 | 80 | 64 | 12.2 | 48 |

AXIAL IMPACT VIBRATION TEST

| Sample size | M20 x 1.0 |

| Frequency | 21Hz |

| Excitation stroke | 11mm |

| Impact stroke | 10mm |

| Vibrating acceleration of excitation table | 10G |

| Test time | 60 minutes |

| Direction of impact | Bolt axis direction |

| Clamping torque | 53.9N.m (550kgf.cm) |

| Sample Nut | Excitation Time (Minutes) 10 20 30 40 50 60 | Test Results | |

| Standard bearing nut with tongued washer | Looseness

|

Nut came off | |

| FUJI Locknut |

|

No effect |

Fuji Locknuts Rotational Life Test

| Sample size | M55 x 2.0 | |

| Speed of revolution | 2,300rpm | |

| Testing cycles | One cycle (forward rotation, stop, reverse rotation, stop): 10 seconds | |

| Stopping time | One forward rotation: 0.30 seconds. For reverse rotation: 0.27 seconds |

| Internal force applied to the nut during stopping | ||

| Sample Nut | Inertial Force : N.m (kgf.cm) | |

| For forward rotation | For reverse rotation | |

| Standard Bearing Nut | 0.14 (1.42) | 0.15 (1.57) |

| FUJI Locknut | 0.15 (1.52) | 0.17 (1.69) |

| RESULTS | ||

| Sample Nut | Sample No | Result on endurance text |

| Standard Bearing Nut & Washer | 1 | Washer damaged & nut came off at approx. 110,000 cycles |

| 2 | Washer damaged & nut came off at approx. 330,000 cycles | |

| FUJI Locknut | 3 | No change after 500,000 cycles |

| 4 | ||

| External view of testing machine | External view of damaged & detached washers (sample No 2) |

BEARING LOCKNUT DIMENSION TABLE

| SC Series | SS Series | SUS Series | Designation of Thread D1 | D3 | D4 | g | T | S | h | H | Perpend-icularity of Bearing Surface | |||||

| FU00SC | FU00SS | FU00SUS | M10x0.75 | 18 | 0-0.5 | 13.5 | 0-0.5 | 14.4 | 0-0.5 | 1.8 | 3 | +0.2 | 4 | 5.2 | +0.3 | 0.05 |

| FU01SC | FU01SS | FU01SUS | M12x1.0 | 22 | 17 | 18.4 | 1.8 | 3 | 4 | 5.4 | ||||||

| FU02SC | FU02SS | FU02SUS | M15x1.0 | 25 | 21 | 21.4 | 1.8 | 4 | 5 | 6.5 | +0.5 | |||||

| FU03SC | FU03SS | FU03SUS | M17x1.0 | 28 | 24 | 24.2 | 1.9 | 4 | 5 | 6.4 | ||||||

| FU04SC | FU04SS | FU04SUS | M20x1.0 | 32 | 26 | 28.4 | 1.8 | 4 | 6 | 7.7 | ||||||

| FU05SC | FU05SS | FU05SUS | M25x1.5 | 38 | 32 | 34 | 2.0 | 5 | 7 | 9.1 | ||||||

| FU06SC | FU06SS | FU06SUS | M30x1.5 | 45 | 38 | 41 | 2.0 | 5 | 7 | 9.1 | +0.8 | |||||

| FU07SC | FU07SS | FU07SUS | M35x1.5 | 52 | 44 | 48 | 2.0 | 5 | 8 | 10.2 | ||||||

| FU08SC | FO08SS | FU08SUS | M40x1.5 | 58 | 50 | 53 | 2.5 | 6 | 9 | 11.2 | ||||||

| FU09SC | FU09SS | FU09SUS | M45x1.5 | 65 | 56 | 60 | 2.5 | 6 | 10 | 12.5 | +1.0 | |||||

| FU10SC | FU10SS | FU10SUS | M50x1.5 | 70 | 61 | 65 | 2.5 | 6 | 11 | 13.5 | ||||||

| FU11SC | FU11SS | FU11SUS | M55x2.0 | 75 | 67 | 69 | 3.0 | 7 | 11 | 13.5 | 0.07 | |||||

| FU12SC | FU12SS | FU12SUS | M60X2.0 | 80 | 73 | 74 | 3.0 | 7 | 11 | 13.5 | ||||||

| FU13SC | FU13SS | FU13SUS | M65x2.0 | 85 | 79 | 79 | 3.0 | 7 | 12 | 15.0 | +1.5 | |||||

| FU14SC | FU14SS | FU14SUS | M70x2.0 | 92 | 85 | 85 | 3.5 | 8 | 12 | 15.0 | ||||||

| FU15SC | FU15SS | FU15SUS | M75x2.0 | 98 | 90 | 91 | 3.5 | 8 | 13 | 15.8 | ||||||

| FU16SC | FU16SS | FU16SUS | M80x2.0 | 105 | 95 | 98 | 3.5 | 8 | 15 | 18.6 | ||||||

| FU17SC | FU17SS | FU17SUS | M85x2.0 | 110 | 102 | 0-0.75 | 103 | 3.5 | 8 | +0.3 | 16 | 19.2 | ||||

| FU18SC | FU18SS | FU18SUS | M90x2.0 | 120 | 108 | 112 | 4.0 | 10 | 16 | 20.3 | ||||||

| FU19SC | FU19SS | FU19SUS | M95x2.0 | 125 | 113 | 117 | 4.0 | 10 | 17 | 21.3 | ||||||

| FU20SC | FU20SS | FU20SUS | M100x2.0 | 130 | 120 | 122 | 4.0 | 10 | 18 | 22.3 | ||||||

| FU21SC | – | – | M105x2.0 | 140 | 126 | 130 | 4.0 | 12 | 18 | 22.3 | ||||||

| FU22SC | – | – | M110x2.0 | 145 | 133 | 135 | 5.0 | 12 | 19 | 23.3 | ||||||

| FU23SC | – | – | M115x2.0 | 150 | 137 | 140 | 5.0 | 12 | 19 | 23.3 | ||||||

| FU24SC | – | – | M120x2.0 | 155 | 138 | 145 | 5.0 | 12 | 20 | 24.3 | ||||||

| FU25SC | – | – | M125x2.0 | 160 | 148 | 150 | 5.0 | 12 | 21 | 25.4 | 0.10 | |||||

| FU26SC | – | – | M130x2.0 | 165 | 149 | 155 | 5.0 | 12 | 21 | 25.4 | +1.5 | |||||

| FU27SC | – | – | M135x2.0 | 175 | 160 | 163 | 6.0 | 14 | 22 | 26.6 | ||||||

| FU28SC | – | – | M140x2.9 | 180 | 160 | 168 | 6.0 | 14 | 22 | 26.6 | ||||||

| FU29SC | – | – | M145x2.0 | 190 | 171 | 178 | 6.0 | 14 | 24 | 28.6 | ||||||

| FU30SC | – | – | M150x2.0 | 195 | 171 | 183 | 6.0 | 14 | 24 | 28.3 | ||||||

Fuji BEARING LOCKNUT MATERIALS

| Material | JIS | ISO | BS |

| SS Low Carbon Steel | SS400 (or equivalent) | 1.0044 | 43B |

| SC High Carbon Steel | S45C (or equivalent) | 1.0503/1.1191/1.1201 | 070M46/080M46/080A47 |

| SUS Stainless Steel | SUS304 (or equivalent) | 1.4301 | 304S31 |

NOTES ON USE

Fine-U-Nuts are used for fastening critical components. When using Fine-U-Nut, strict compliance with the following is required:

A lead in chamfer equivalent to one thread pitch is required. The screw thread should be to ISO 965. (Tolerance Class 6g)

Lubricate the shaft before assembly or removal of the nut. With shafts of low hardness use a high performance lubricant.

To maximise effectiveness ensure there are at least two full threads beyond the friction ring.

The squareness specified for the mating face is achieved with a tightening torque equivalent to x2 the prevailing torque – see our literature.

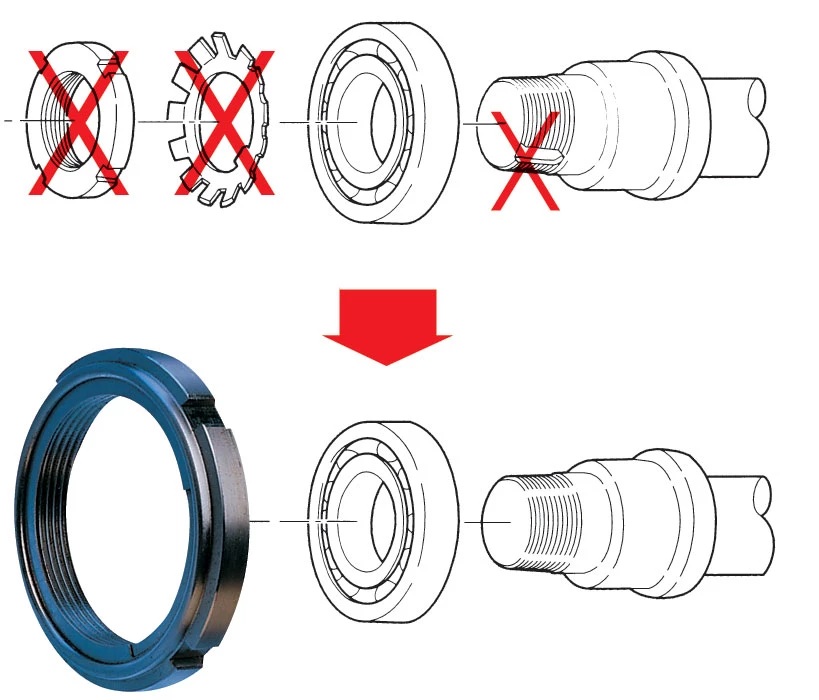

Do NOT use a high rotational speed impact wrench.

Do NOT use the nuts on shafts with keyways.

Do NOT screw in the nut from the friction ring side.

Stop using the nut when excessive deformation or other fault is found in the friction ring and the clamp.

For severe or unusual applications please ask for our advice on 01202 339559.

Utilise our customised Bearing Selector tool here.

Related products

Bearings

Fey Laminar Seal Rings