Fey Laminar Seal Rings

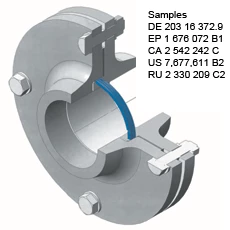

With over 75 years of expertise, IEC supplies the UK with Fey laminar seal rings – also known as Fey sealing rings, Fey labyrinth sealing rings, or simply Fey rings. These metallic, low-contact sealing solutions reduce friction, resist wear, and ensure reliable performance in demanding environments for both static and rotating components.

Fey Labyrinth Sealing Rings

Protect vulnerable seals and bearings

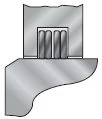

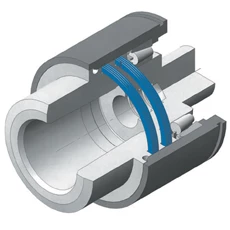

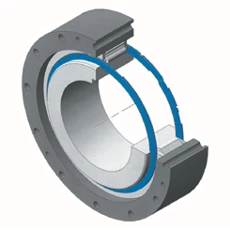

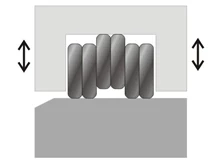

Fey labyrinth sealing rings, a precision-engineered type of Fey sealing ring, use a multi-layer labyrinth design with minimal gap widths. This configuration lowers friction, limits heat build-up, and extends service life. Ideal for both rotating shafts and static housings, Fey labyrinth sealing rings deliver dependable protection in tough conditions – including high temperatures, corrosive environments, and heavy-duty industrial applications.

- Reduces premature component failure and equipment damage

- Suitable for high temperature and corrosive environments

- Available in sizes from 15mm to 1300mm

- Custom designed and available from stock

- ISO 9001 and TS16949 certified manufacturers

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.

Markets

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Markets

IEC have a range of mechanical solutions to suit a broad spectrum of markets and applications, from aerospace to skateboards.

Case Studies

We act as partners, making our customers’ engineering challenges ours to solve, removing stress and freeing up time to turn ideas in to innovation.

Product:

Application:

Challenge:

Solution:

Product:

Application:

Challenge:

Solution:

Fey Catalogue

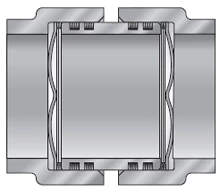

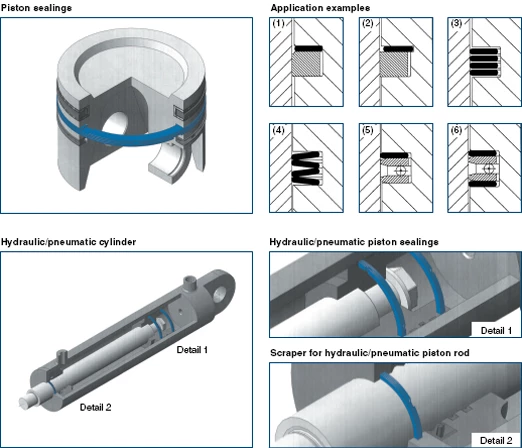

Fey rings, including Fey labyrinth sealing rings, are essential for both rotating and static applications. These rings utilise a low-contact, multi-labyrinth design with minimal gap width, producing low friction and reducing internal heat and wear. This unique design ensures excellent sealing characteristics, making them perfect for high-speed, high-temperature, and friction-sensitive applications.

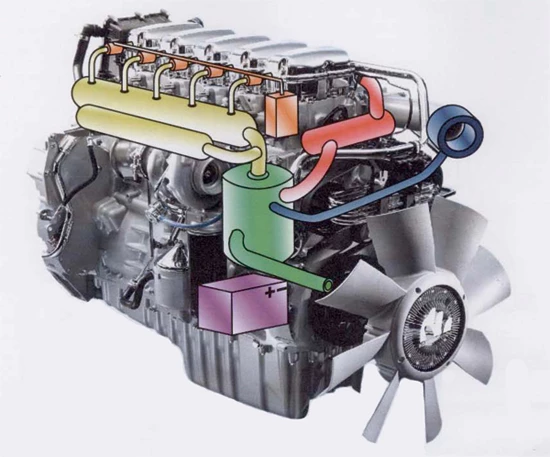

Fey labyrinth sealing rings excel in hot environments, providing effective sealing for grease and excluding dust, dirt, and fluids in roller and plain bearing assemblies. They are available in sizes from 15mm to 1300mm, with the standard spring steel version suitable for temperatures up to 300°C. Nickel-chrome steel variants can withstand temperatures up to 720°C, making them ideal for automotive engine applications, such as sealing valves or axial compensators on exhaust gas pipes, EGR, and turbochargers in diesel engines.

Special sizes of Fey rings can be produced in small batches cost-effectively. Fey holds ISO9001, 14001, and TS16949 approvals, ensuring high-quality standards.

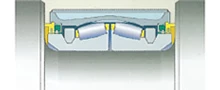

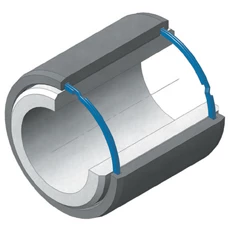

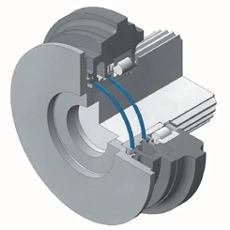

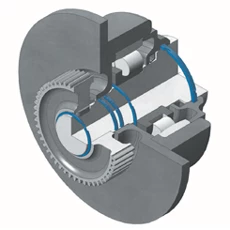

Fey provides single and double wound laminar retaining rings for applications requiring axial part fixation. These rings offer several advantages, including strong 360° contact with the groove bottom, continuous support around the circumference, reliable retention under high axial load, and flawless material integrity. They are commonly used in transmissions for agricultural and construction equipment, shipbuilding, aerospace, automotive applications, winches, pulleys, roller bearings, and vertical drive shafts.

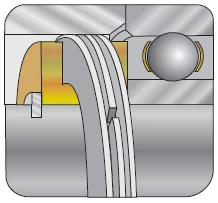

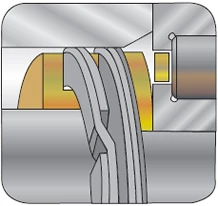

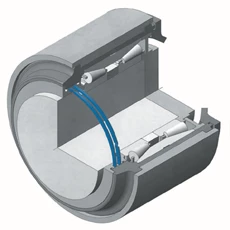

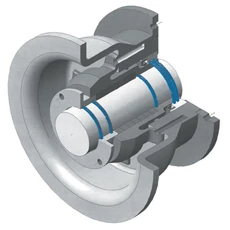

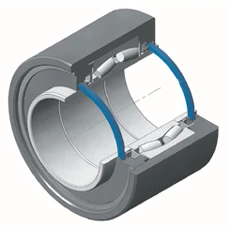

These moulded plastic components, paired with Fey labyrinth sealing rings, serve as spacers and seals for grease-lubricated bearings. They can feature an additional sealing lip for high-splash water environments.

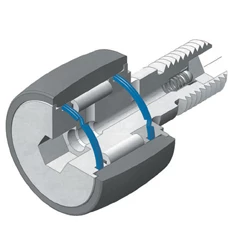

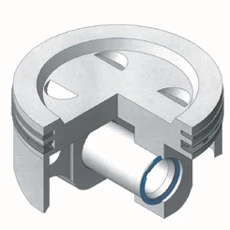

Fey piston rings complement cast iron piston rings in both rebuilt and new engines, suitable for hydraulic and pneumatic pistons or shock absorbers. They are also used in freedom and drop forging machines and presses.

By incorporating Fey rings into your applications, you ensure high performance, durability, and reliability in even the most demanding environments. Explore our product range to find the perfect solution for your needs.

Fey LABYRINTH SEALING RINGS

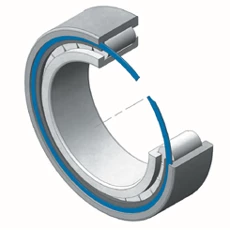

Single wound FK 3 labyrinth sealing rings are used as grease seals for plain and roller bearing to provide protection against the ingress of dust and environmental moisture. The combined ASK or ISK ring optimise the sealing through the increased labyrinth effect.

Due to easier fitting in the grooves, IS or ISK is preferred over the AS or ASK where this is possible. The ring carriers can be manufactured from steel, cast iron or plastic.

Single and double wound rings are manufactured from special materials and use special processes. FK 5 and FK 5-HFL rings are used when applications require extreme temperature and corrosion resistant properties. Single and double wound laminar sealing rings are used for both rotating and static applications.

FK 5 Sealing Rings

FK 5 sealing rings are designed to handle applications where high temperature and corrosion resistance is required. This makes an excellent sealing solution for primary metals operations. For many years major manufacturers of continuous casting lines have been using double wound Fey Laminar Sealing rings to seal their bearings.

FK 5 – HFL Sealing Rings

FEY created their FK 5-HFL laminar sealing ring series to handle the demands of applications where gases need to be sealed under pressure and extremely high temperatures. Features of this series come from years of design experience.

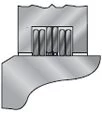

FK 6 laminar rings are double wound. They serve as a grease seal for plain and roller bearings and are also used as a protective seal in front of radial lip seals. Higher sealing performance is achieved by the FK 6 laminar rings when exuding grease. They also provide better protection against dust, dirt and splash water. FK 6 laminar rings are outstanding for their high retention force and have no joint gap. The combined ASKD or ISKD ring sets optimize the sealing as a result of the increased labyrinth effect.

Due to easier fitting in the grooves the ISD or ISKD arrangement is preferred over the ASD or ASKD arrangement where this is possible. The ring carriers can be manufactured from steel, cast iron or plastic.

Fey FK3 SINGLE WOUND LABYRINTH SEALING RINGS

Single wound FK 3 labyrinth sealing rings are used as grease seals for plain and roller bearing to provide protection against the ingress of dust and environmental moisture. The combined ASK or ISK ring optimise the sealing through the increased labyrinth effect.

FK3 Dimensions Table

| Bore Shaft | Ring Dimensions | Groove Width | Groove Ø | Grove Ø | ||

| D | RB | RD | A | B | D1 | D2 |

| 15-24.9 25-29.9 30-35.9 | 1.0 1.2 1.5 | 0.65 0.65 0.65 | 2.2 2.2 2.2 | 3.6 3.6 3.6 | D – 2.6 D – 3.0 D – 3.6 | D + 2.6 D + 3.0 D + 3.6 |

| 36-42.9 43-48.9 49-51.9 | 1.8 2.2 2.4 | 0.65 0.72 0.72 | 2.2 2.4 2.4 | 3.6 4.0 4.0 | D – 4.2 D – 5.0 D – 5.4 | D + 4.2 D + 5.0 D + 5.4 |

| 52-59.9 60-69.9 70-74.9 | 2.6 2.6 3.1 | 0.72 0.82 0.82 | 2.4 2.7 2.7 | 4.0 4.5 4.5 | D – 5.8 D – 6.2 D – 6.8 | D + 5.8 D + 6.2 D + 6.8 |

| 75-79.9 80-89.9 90-99.9 | 3.3 3.5 3.8 | 0.82 0.82 0.82 | 2.7 2.7 2.7 | 4.5 4.5 4.5 | D – 7.2 D – 7.6 D – 8.2 | D + 7.2 D + 7.6 D + 8.2 |

| 100-104.9 105-109.9 110-119.9 | 4.1 4.3 4.5 | 0.82 0.98 0.98 | 2.7 3.3 3.3 | 4.5 5.5 5.5 | D – 8.8 D – 9.2 D – 9.8 | D + 8.8 D + 9.2 D + 9.8 |

| 120-129.9 130-149.9 150-170.9 | 5.0 5.5 6.0 | 0.98 0.98 1.0 | 3.3 3.3 3.4 | 5.5 5.5 5.6 | D – 10.8 D – 11.8 D – 13.0 | D + 10.8 D + 11.8 D + 13.0 |

| 150-170.0 171-199.9 171-199.9 | *6.0 7.0 *7.0 | 1.5 1.0 1.5 | 5.1 3.4 5.1 | 8.2 5.6 8.2 | D – 13.0 D – 15.0 D – 15.0 | D + 13.0 D + 15.0 D + 15.0 |

| 200-259.9 200-259.9 200-259.9 | 8.0 *8.0 9.0 | 1.2 1.5 1.5 | 4.1 5.1 5.1 | 6.6 8.2 8.2 | D – 18.0 D – 18.0 D – 20.0 | D + 18.0 D + 18.0 D + 20.0 |

| 320-399.9 400-439.9 440-600.9 | 10.0 11.0 12.0 | 1.5 1.5 1.5 | 5.2 5.2 5.2 | 8.3 8.3 8.3 | D – 22.0 D – 24.0 D – 26.0 | D + 22.0 D + 24.0 D + 26.0 |

| 440-600.9 601-699.9 700-799.9 | *12.0 14.0 16.0 | 2.5 2.5 2.5 | 8.3 8.3 8.3 | 13.5 13.5 13.5 | D – 26.0 D – 32.0 D – 36.0 | D + 26.0 D + 32.0 D + 36.0 |

| 800-899.9 900-999.9 1000-1300 | 18.0 20.0 22.0 | 2.5 2.5 2.5 | 8.3 8.3 8.4 | 13.5 13.5 13.6 | D – 40.0 D – 44.0 D – 48.0 | D + 40.0 D + 44.0 D + 48.0 |

Due to easier fitting in the grooves, IS or ISK is preferred over the AS or ASK where this is possible. The ring carriers can be manufactured from steel, cast iron or plastic.

AS

Outside Clamping

3 rings = 1 set

No speed limit for housing or ring carrier

ASK

Outside Clamping Combination

5 rings = 1 set

Speed limit for housing max 10m/s

Speed limit for ring carrier max 4m/s

IS

Inside Clamping

3 rings = 1 set

No speed limit for housing

Speed limit for shaft max 4m/s

ISK

Inside Clamping Combination

5 rings = 1 set

Speed limit for shaft max 4m/s

Speed limit for housing max 10m/s

FK3 AS SINGLE LAMINAR SEALING RINGS FOR BORES

Application FK3 AS ‘Outside clamping single laminar sealing rings (1 set = 3 rings)

Single wound laminar sealing rings “FK3 AS” are used as a grease seal for roller and plain bearings and they protect, if greased, against dust entry and ambient moisture. The combined ring sets “FK3 ASK” (additional sealing of the groove base diameter) optimize the sealing effect due to the increased labyrinth effect.

The “FK3 AS” or “FK3 ASK” assemblies are normally preferred over the “FK3 IS” or “FK3 ISK” assemblies due to their easier installation into the grooves. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK3 AS ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 3 AS rings).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK3 ASK SINGLE LAMINAR SEALING RINGS COMBINED FOR BORES

Application FK3 ASK ‘Outside clamping combined single laminar sealing rings (1 set = 5 rings)

Single wound laminar sealing rings ‘FK3 ASK’ are used as a grease seal for roller and plain bearings and they

protect, if greased, against dust entry and ambient moisture. Due to the increased labyrinth effect, the sealing effect is optimized by the additional sealing of the groove base diameter.

The “FK3 AS” or “FK3 ASK” assemblies are normally preferred over the “FK3 IS” or “FK3 ISK” assemblies due to their easier installation into the grooves. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK3 AS ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 3 AS rings + 2 IS rings).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK3 ISK SINGLE LAMINAR SEALING RINGS COMBINED FOR SHAFTS

Application FK3 ISK ‘Inside clamping combined single rings’ (1 set = 5 rings)

Single wound laminar sealing rings “FK3 ISK” are used as a grease seal for roller and plain bearings and they protect, if greased, against dust entry and ambient moisture. Due to the increased labyrinth effect, the sealing effect is optimized by the additional sealing of the groove base diameter.

The “FK3 AS” or “FK3 ASK” assemblies are normally preferred over the “FK3 IS” or “FK3 ISK” assemblies due to their easier installation into the grooves. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK3 AS ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 3 IS rings + 2 AS rings).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK5 / FK5-HFL SINGLE & DOUBLE WOUND LAMINAR SEALING RINGS

Single and double wound rings are manufactured from special materials and use special processes. FK5 and FK5-HFL rings are used when applications require extreme temperature and corrosion resistant properties. Single and double wound laminar sealing rings are used for both rotating and static applications.

FK 5 Sealing Rings

FK5 sealing rings are designed to handle applications where high temperature and corrosion resistance is required. This makes an excellent sealing solution for primary metals operations. For many years major manufacturers of continuous casting lines have been using double wound Fey Laminar Sealing rings to seal their bearings.

FK5 Single Ring Dimensions / FK5 Double Ring Dimensions / FK5 Application

FK5-HFL Sealing Rings

FEY created their FK5-HFL laminar sealing ring series to handle the demands of applications where gases need to be sealed under pressure and extremely high temperatures. Features of this series come from years of design experience.

FK5-HFL Dimensions / FK5-HFL Application

FK5 SINGLE & DOUBLE LAMINAR SEALING RINGS

For roller bearings of continuous casting plants, steam turbines and power units

FK5 application single and double laminar sealing rings

Single and double wound laminar sealing rings are used for sealing the roller and plain bearings on the segments rolls for continuous casting plants, industrial steam turbines, mobile and stationary power units. Basically everywhere the sealing system must meet severe requirements due to extreme operating conditions.

This includes corrosion or media resistance of the ring material, high operating temperatures and high contamination levels.

Continuous casting plant diagram

Floating bearing (example)

Fixed bearing (example)

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK5-HFL SINGLE & DOUBLE LAMINAR SEALING RINGS

For the sealing of axial compensators in exhaust pipes of internal combustion engines, manifold sheet metal pipe connections, exhaust gas recirculation systems and turbochargers

“FK5-HFL” application single and double laminar sealing rings

Single and double wound laminar sealing rings with the identification “FK5-HFL” are made from high-temperature chrome-nickel steels and are designed for the sealing for axial and radial compensators at exhaust pipes of internal combustion engines, exhaust gas recirculation systems, exhaust valves, turbochargers, mobile and stationary power units. Especially for applications that deal with high operating temperatures and high axial and radial movements due to thermal expansions.

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK6 ASKD DOUBLE LAMINAR SEALING RINGS COMBINED FOR BORES

Application FK6 ASD ‘Outside clamping double rings’ (1 set = 2 rings)

In contrast to the single wound laminar sealing rings “FK3”, “FK6” laminar rings are double wound. They are used as grease seals for roller and plain bearings. They are also used as a protection seal in front of hermetically acting seal arrangements. The “FK6” laminar rings must meet special sealing requirements against grease leakage and against dust, dirt and splash water ingress. “FK6” laminar rings provide a uniform radial tension and, in contrast to the “FK3” laminar rings, they have no axial joint gap. The combined ring sets “FK6 ASKD” (additional sealing of the groove base diameter) optimize the sealing effect due to the increased labyrinth effect.

The “FK6 ASD” or “FK6 ASKD” assemblies are normally preferred over the “FK6 ISD” or “FK6 ISKD” due to their easier ring installation into the grooves of the ring carriers. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

FK6 ASD ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 2 ASD rings + 1 ISD ring).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK6 DOUBLE WOUND LAMINAR SEALING RINGS

FK6 laminar rings are double wound. They serve as a grease seal for plain and roller bearings and are also used as a protective seal in front of radial lip seals. Higher sealing performance is achieved by the FK6 laminar rings when exuding grease. They also provide better protection against dust, dirt and splash water. FK6 laminar rings are outstanding for their high retention force and have no joint gap. The combined ASKD or ISKD ring sets optimize the sealing as a result of the increased labyrinth effect.

FK6 Dimensions Table

Due to easier fitting in the grooves the ISD or ISKD arrangement is preferred over the ASD or ASKD arrangement where this is possible. The ring carriers can be manufactured from steel, cast iron or plastic.

ASD

Outside Clamping Double Rings

2 rings = 1 set

No speed limit for housing or ring carrier

ASKD

Outside Clamping Duuble Rings Combination

3 rings = 1 set

No speed limit for housing

Speed limit for ring carrier max 10m/s

FK5/FK6 DOUBLE WOUND LAMINAR SEALING RINGS

| Bore Shaft | Ring Dimensions | Groove Width | Groove Ø | Grove Ø | ||

| D | RB | RD | A | B | D1 | D2 |

| 15-24.9 25-29.9 30-35.9 | 1.0 1.2 1.5 | 1.3 1.3 1.3 | 2.9 2.9 2.9 | 4.3 4.3 4.3 | D – 2.6 D – 3.0 D – 3.6 | D + 2.6 D + 3.0 D + 3.6 |

| 36-42.9 43-48.9 49-51.9 | 1.8 2.2 2.4 | 1.3 1.45 1.45 | 2.9 3.2 3.2 | 4.3 4.8 4.8 | D – 4.2 D – 5.0 D – 5.4 | D + 4.2 D + 5.0 D + 5.4 |

| 52-59.9 60-69.9 70-74.9 | 2.6 2.6 3.1 | 1.45 1.65 1.65 | 3.2 3.6 3.6 | 4.8 5.4 5.4 | D – 5.8 D – 6.2 D – 6.8 | D + 5.8 D + 6.2 D + 6.8 |

| 75-79.9 80-89.9 90-99.9 | 3.3 3.5 3.8 | 1.65 1.65 1.65 | 3.6 3.6 3.6 | 5.4 5.4 5.4 | D – 7.2 D – 7.6 D – 8.2 | D + 7.2 D + 7.6 D + 8.2 |

| 100-104.9 105-109.9 110-119.9 | 4.1 4.3 4.6 | 1.65 1.96 1.96 | 3.6 4.3 4.3 | 5.4 6.4 6.4 | D – 8.8 D – 9.2 D – 9.8 | D + 8.8 D + 9.2 D + 9.8 |

| 120-129.9 130-149.9 150-170.9 | 5.0 5.5 6.0 | 1.96 1.96 2.0 | 4.3 4.3 4.4 | 6.4 6.4 6.5 | D – 10.8 D – 11.8 D – 13.0 | D + 10.8 D + 11.8 D + 13.0 |

| 150-170.0 171-199.9 171-199.9 | *6.0 7.0 *7.0 | 3.0 2.0 3.0 | 6.5 4.4 6.5 | 9.6 6.5 9.6 | D – 13.0 D – 15.0 D – 15.0 | D + 13.0 D + 15.0 D + 15.0 |

| 200-259.9 200-259.9 260-319.9 | 8.0 *8.0 9.0 | 2.4 3.0 3.0 | 5.3 6.5 6.5 | 7.8 9.6 9.6 | D – 18.0 D – 18.0 D – 20.0 | D + 18.0 D + 18.0 D + 20.0 |

| 320-399.9 400-439.9 440-600.9 | 10.0 11.0 12.0 | 3.0 3.0 3.0 | 6.6 6.6 6.6 | 9.8 9.8 9.8 | D – 22.0 D – 24.0 D – 26.0 | D + 22.0 D + 24.0 D + 26.0 |

| 440-600.9 601-699.9 700-799.9 | *12.0 14.0 16.0 | 5.0 5.0 5.0 | 10.6 10.8 10.8 | 45.9 16.2 16.2 | D – 26.0 D – 32.0 D – 36.0 | D + 26.0 D + 32.0 D + 36.0 |

| 800-899.9 900-999.9 1000-1300 | 18.0 20.0 22.0 | 5.0 5.0 5.0 | 11.0 11.0 11.0 | 16.5 16.5 16.5 | D – 40.0 D – 44.0 D – 48.0 | D + 40.0 D + 44.0 D + 48.0 |

FK5-HFL SINGLE & DOUBLE LAMINAR SEALING RINGS

| Bore Shaft | Ring Dimensions | Groove Width | Groove Ø | |||

| D | RB | RD | A | B | D1 | |

| 30–39.9 40 49.9 50–59.9 | 2.2 2.2 2.6 | 1.45 1.45 1.45 | Groove dimensions are available on request Please contact us | |||

| 60 69.9 70–79.9 80–89.9 | 2.8 3.3 3.8 | 1.65 1.65 1.65 | ||||

| 90–104.9 105–119.9 120-140 | 4.1 4.5 5.0 | 1.65 1.95 1.95 | ||||

FK6 ASD DOUBLE LAMINAR SEALING RINGS FOR BORES

Application FK6 ASD ‘Outside clamping double rings’ (1 set = 2 rings)

In contrast to the single wound laminar sealing rings “FK3”, “FK6” laminar rings are double wound. They are used as grease seals for roller and plain bearings. They are also used as a protection seal in front of hermetically acting seal arrangements. The “FK6” laminar rings must meet special sealing requirements against grease leakage and against dust, dirt and splash water ingress. “FK6” laminar rings provide a uniform radial tension and, in contrast to the “FK3” laminar rings, they have no axial joint gap. The combined ring sets “FK6 ASKD” (additional sealing of the groove base diameter) optimize the sealing effect due to the increased labyrinth effect.

The “FK6 ASD” or “FK6 ASKD” assemblies are normally preferred over the “FK6 ISD” or “FK6 ISKD” due to their easier ring installation into the grooves of the ring carriers. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

FK6 ASD ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 2 ASD rings).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK6 ISD DOUBLE LAMINAR SEALING RINGS FOR SHAFTS

Application FK6 ISD ‘Inside clamping double rings’ (1 set = 2 rings)

Double wound laminar sealing rings “FK6 ISD” are used as a grease seal for roller and plain bearings and they protect, if greased, against grease leakage as well as against dust, dirt and splash water ingress, especially if the sealing requirements are high. Double wound laminar rings provide a uniform radial tension and, in contrast to the single wound “FK3” laminar rings, they have no axial joint gap. The combined ring sets “FK6 ISKD” (additional sealing of the groove base diameter) optimize the sealing effect due to the increased labyrinth effect.

The “FK6 ASD” or “FK6 ASKD” assemblies are normally preferred over the “FK6 ISD” or “FK6 ISKD” assemblies due to their easier installation into the grooves. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK6 ASD ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 2 ISD rings).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK6 ISKD DOUBLE LAMINAR SEALING RINGS COMBINED FOR SHAFTS

Application FK6 ISKD ‘Inside clamping combined double rings’ (1 set = 3 rings)

Double wound laminar sealing rings “FK6 ISKD” are used as a grease seal for roller and plain bearings and they protect, if greased, against grease leakage as well as against dust, dirt and splash water ingress, especially if the sealing requirements are high. Due to the increased labyrinth effect, the sealing effect is optimized by the additional sealing of the groove base diameter.

The “FK6 ASD” or “FK6 ASKD” assemblies are normally preferred over the “FK6 ISD” or “FK6 ISKD” assemblies due to their easier installation into the grooves. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK6 ASD ring set

Axial and/or Radial Play

The groove width ‘A’ must be widened by twice the play if play occurs in the area of the rings. The groove base diameter ‘D2’ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occur if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions ‘D1’ for all enquiries and/or orders. The rings can be ordered individually or in sets (1 set = 2 ISD rings + 1 ASD ring).

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK7 DSB DOUBLE WOUND LAMINAR RETAINING RINGS FOR BORES

Application “FK7 DSB” Double retaining ring bore

The double wound laminar retaining rings “FK7 DSB” for bores are a valuable addition to the single wound laminar retaining rings “FK7 ESB”. The application range for the double wound laminar retaining rings “FK7 DSB” for bores includes applications where the components need to be axially retained, e.g. for transmission systems, construction equipment and agriculture machinery, for fastening elements in the automotive industry and mechanical engineering, in the roller and plain bearing industry, for ship and aircraft building, winches, pulleys, etc.

Advantages of the double wound laminar retaining rings:

- Roundness of the closed winding over a range of 360° guarantees fixed contact to the groove base and full circumferential tightness.

- Uniform dynamic weight during rotation

- Higher axial resilience as compared to the single wound laminar retaining rings “FK7 ESB”

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK7 DMS ring

Axial Stress

Shearing tests under operating conditions must be performed to determine the axial shearing capacity of the retaining rings. The secure position of the retaining rings in the groove cannot be guaranteed if the surrounding components thrust uncontrollable against the laminar rings during operation (coupling effect) or if the components vibrate extremely.

Ordering Information

The ring diameter information must match bore dimensions ‘D1’ for all enquiries and/or orders.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar rings can begin to determine whether the desired sealing effects can be achieved.

FK7 DMS DOUBLE WOUND LAMINAR RETAINING RINGS FOR SHAFTS

Application “FK7 DMS” Double retaining ring shaft with centrifugal force protection

“FK7 DMS” double laminar retaining rings with centrifugal force protection can be used for rotational speeds that cannot be achieved by “FK7 DSW” retaining rings.

Diameter range for DMS rings: Ø 45 mm to Ø 310 mm.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK7 DMS ring

Axial Stress

Shearing tests under operating conditions must be performed to determine the axial shearing capacity of the retaining rings. The secure position of the retaining rings in the groove cannot be guaranteed if the surrounding components thrust uncontrollable against the laminar rings during operation (coupling effect) or if the components vibrate extremely.

Ordering Information

The ring diameter information must match bore dimensions ‘D1’ for all enquiries and/or orders.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar rings can begin to determine whether the desired sealing effects can be achieved.

FK7 DSW DOUBLE WOUND LAMINAR RETAINING RINGS FOR SHAFTS

Application “FK7 DSW” Double retaining ring shaft

The double wound laminar retaining rings “FK7 DSW” for shafts are a valuable addition to the single wound laminar retaining rings “FK7 ESW”. The application range for the double wound laminar retaining rings “FK7 DSW” for shafts includes applications where the components need to be axially retained, e.g. for transmission systems, construction equipment and agriculture machinery, for fastening elements in the automotive industry and mechanical engineering, in the roller and plain bearing industry, for ship and aircraft building, winches, pulleys, etc.

Advantages of the double wound laminar retaining rings:

- Roundness of the closed winding over a range of 360° guarantees fixed contact to the groove base and full circumferential tightness.

- Uniform dynamic weight during rotation.

- Higher axial resilience as compared to the single wound laminar retaining rings “FK7 ESW”

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK7 DMS ring

Axial Stress

Shearing tests under operating conditions must be performed to determine the axial shearing capacity of the retaining rings. The secure position of the retaining rings in the groove cannot be guaranteed if the surrounding components thrust uncontrollable against the laminar rings during operation (coupling effect) or if the components vibrate extremely.

Ordering Information

The ring diameter information must match bore dimensions ‘D1’ for all enquiries and/or orders.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar rings can begin to determine whether the desired sealing effects can be achieved.

FK7 DMS DOUBLE WOUND LAMINAR RETAINING RINGS FOR SHAFTS

| Bore Ø DB | RB | RD | NB | DN = DB+ |

| 45 – 51.9 52 – 59.9 60 – 69.9 | 3.5 3.5 3.5 | 1.65 1.65 1.65 | 1.8 1.8 1.8 | – 2.0 – 2.0 – 2.0 |

| 70 – 74.0 75 – 79.9 80 – 89.9 | 4.1 4.3 4.6 | 1.65 1.98 1.98 | 1.8 2.15 2.15 | – 2.5 – 2.5 – 2.8 |

| 90 – 99.9 100 – 109.9 110 – 129.9 | 5.0 5.5 6.0 | 1.98 1.98 2.0 | 2.15 2.15 2.15 | – 3.0 – 3.0 – 3.0 |

| 130 – 149.9 150 – 169.9 170 – 199.9 | 6.0 7.0 8.0 | 3.0 3.0 3.0 | 3.15 3.15 3.15 | – 3.5 – 4.0 – 5.0 |

| 200 – 259.9 260 – 310 | 9.0 10.0 | 3.0 3.0 | 3.15 3.15 | – 5.0 – 5.5 |

FK7 DSB DOUBLE WOUND LAMINAR RETAINING RINGS FOR BORES

| Bore Ø DB | RB | RD | NB | DN = DB+ |

15-20.9 21-29.9 | 1.5 1.8 | 1.3 1.3 | 1.45 1.45 | + 0.8 + 0.9 |

30-35.9 36-42.9 | 2.2 2.8 | 1.45 1.65 | 1.6 1.8 | + 1.2 + 1.6 |

43-51.9 52-59.9 | 3.1 3.5 | 1.65 1.65 | 1.8 1.8 | + 1.8 + 2.0 |

60-69.9 70-74.9 | 3.8 4.1 | 1.65 1.65 | 1.8 1.8 | + 2.0 + 2.5 |

75-79.9 80-89.9 | 4.3 4.6 | 1.98 1.98 | 2.15 2.15 | + 2.5 + 2.8 |

90-99.9 100-109.9 | 5.0 5.5 | 1.98 1.98 | 2.15 2.15 | + 3.0 + 3.0 |

110-129.9 130-149.9 | 6.0 6.0 | 2.0 3.0 | 2.2 3.2 | + 3.5 + 3.5 |

150-169.9 170-199.9 | 7.0 8.0 | 3.0 3.0 | 3.2 3.2 | + 4.0 + 5.0 |

200-259.9 260-319.9 | 9.0 10.0 | 3.0 3.0 | 3.2 3.2 | + 5.0 + 5.5 |

320-399.9 400-439.9 | 11.0 12.0 | 3.0 3.0 | 3.2 3.2 | + 6.0 + 7.0 |

440- 599.9 600-699.9 | 12.0 14.0 | 5.0 5.0 | 5.3 5.3 | + 7.0 + 8.0 |

700-799.9 800-899.9 | 16.0 18.0 | 5.0 5.0 | 5.3 5.3 | + 9.0 + 10.0 |

900-999.9 1000-1300 | 20.0 22.0 | 5.0 5.0 | 5.3 5.3 | + 11.0 + 12.0 |

FK7 DSW DOUBLE WOUND LAMINAR RETAINING RINGS FOR SHAFTS

| Bore Ø DB | RB | RD | NB | DN = DB+ |

15-20.9 21-29.9 | 1.5 1.8 | 1.3 1.3 | 1.45 1.45 | + 0.8 + 0.9 |

30-35.9 36-42.9 | 2.2 2.8 | 1.45 1.65 | 1.6 1.8 | + 1.2 + 1.6 |

43-51.9 52-59.9 | 3.1 3.5 | 1.65 1.65 | 1.8 1.8 | + 1.8 + 2.0 |

60-69.9 70-74.9 | 3.8 4.1 | 1.65 1.65 | 1.8 1.8 | + 2.0 + 2.5 |

75-79.9 80-89.9 | 4.3 4.6 | 1.98 1.98 | 2.15 2.15 | + 2.5 + 2.8 |

90-99.9 100-109.9 | 5.0 5.5 | 1.98 1.98 | 2.15 2.15 | + 3.0 + 3.0 |

110-129.9 130-149.9 | 6.0 6.0 | 2.0 3.0 | 2.2 3.2 | + 3.5 + 3.5 |

150-169.9 170-199.9 | 7.0 8.0 | 3.0 3.0 | 3.2 3.2 | + 4.0 + 5.0 |

200-259.9 260-319.9 | 9.0 10.0 | 3.0 3.0 | 3.2 3.2 | + 5.0 + 5.5 |

320-399.9 400-439.9 | 11.0 12.0 | 3.0 3.0 | 3.2 3.2 | + 6.0 + 7.0 |

440-599.9 600-699.9 | 12.0 14.0 | 5.0 5.0 | 5.3 5.3 | + 7.0 + 8.0 |

700-799.9 800-899.9 | 16.0 18.0 | 5.0 5.0 | 5.3 5.3 | + 9.0 + 10.0 |

900-999.9 1000-1300 | 20.0 22.0 | 5.0 5.0 | 5.3 5.3 | + 11.0 + 12.0 |

FK7 ESB SINGLE WOUND LAMINAR RETAINING RINGS FOR BORES

| Bore Ø DB | RB | RD | NB | DN = DB+ |

| 15-20.9 21-29.9 | 1.5 1.8 | 0.65 0.65 | 0.75 0.75 | + 0.8 + 0.9 |

| 30-35.9 36-42.9 | 2.2 2.8 | 0.72 0.82 | 0.85 0.95 | + 1.2 + 1.6 |

| 43-51.9 52-59.9 | 3.1 3.5 | 0.82 0.82 | 0.95 0.95 | + 1.8 + 2.0 |

| 60-69.9 70-74.9 | 3.8 4.1 | 0.82 0.82 | 0.95 0.95 | + 2.0 + 2.5 |

| 75-79.9 80-89.9 | 4.3 4.6 | 0.98 0.98 | 1.1 1.1 | + 2.5 + 2.8 |

| 90-99.9 100-109.9 | 5.0 5.5 | 0.98 0.98 | 1.1 1.1 | + 3.0 + 3.0 |

| 110-129.9 130-149.9 | 6.0 6.0 | 1.0 1.5 | 1.15 1.65 | + 3.5 + 3.5 |

| 150-169.9 170-199.9 | 7.0 8.0 | 1.5 1.5 | 1.65 1.65 | + 4.0 + 5.0 |

| 200-259.9 260-319.9 | 9.0 10.0 | 1.5 1.5 | 1.65 1.65 | + 5.0 + 5.5 |

| 320-399.9 400 -439.9 | 11.0 12.0 | 1.5 1.5 | 1.65 1.65 | + 6.0 + 7.0 |

| 440-599.9 600-699.9 | 12.0 14.0 | 2.5 2.5 | 2.7 2.7 | + 7.0 + 8.0 |

| 700-799.9 800-899.9 | 16.0 18.0 | 2.5 2.5 | 2.7 2.7 | + 9.0 + 10.0 |

| 900-999.9 1000-1300 | 20.0 22.0 | 2.5 2.5 | 2.7 2.7 | + 11.0 + 12.0 |

FK7 ESB SINGLE WOUND LAMINAR RETAINING RINGS FOR BORES

Application “FK7 DSB” Double retaining ring bore

The double wound laminar retaining rings “FK7 DSB” for bores are a valuable addition to the single wound laminar retaining rings “FK7 ESB”. The application range for the double wound laminar retaining rings “FK7 DSB” for bores includes applications where the components need to be axially retained, e.g. for transmission systems, construction equipment and agriculture machinery, for fastening elements in the automotive industry and mechanical engineering, in the roller and plain bearing industry, for ship and aircraft building, winches, pulleys, etc.

Advantages of the double wound laminar retaining rings:

- Roundness of the closed winding over a range of 360° guarantees fixed contact to the groove base and full circumferential tightness.

- Uniform dynamic weight during rotation

- Higher axial resilience as compared to the single wound laminar retaining rings “FK7 ESB”

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK7 DMS ring

Axial Stress

Shearing tests under operating conditions must be performed to determine the axial shearing capacity of the retaining rings. The secure position of the retaining rings in the groove cannot be guaranteed if the surrounding components thrust uncontrollable against the laminar rings during operation (coupling effect) or if the components vibrate extremely.

Ordering Information

The ring diameter information must match bore dimensions ‘D1’ for all enquiries and/or orders.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar rings can begin to determine whether the desired sealing effects can be achieved.

FK7 ESW SINGLE WOUND LAMINAR RETAINING RINGS FOR SHAFTS

Application “FK7 ESB” Single retaining ring bore

The application range for the single wound laminar retaining rings “FK7 ESB” for bores includes applications where the components need to be axially retained, e.g. for transmission systems, construction equipment and agriculture machinery, for fastening elements in the automotive industry and mechanical engineering, in the roller and plain bearing industry, for ship and aircraft building, winches, pulleys, etc.

Assembly/disassembly features are special options for single wound laminar retaining rings.

Permissible circumferential speed (in m/s)

Axial and/or radial play

FK7 DMS ring

Axial Stress

Shearing tests under operating conditions must be performed to determine the axial shearing capacity of the retaining rings. The secure position of the retaining rings in the groove cannot be guaranteed if the surrounding components thrust uncontrollable against the laminar rings during operation (coupling effect) or if the components vibrate extremely.

Ordering Information

The ring diameter information must match bore dimensions ‘D1’ for all enquiries and/or orders.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar rings can begin to determine whether the desired sealing effects can be achieved.

FK8 PLASTIC LAMINAR RING CARRIER SEALS - APPLICATION

as seals and spacers for grease lubricated roller bearings

Application “FK8” plastic laminar ring carrier seals

Outside clamping plastic ring carrier seals made from Polyamide 6 (PA6), also available with mineral fibre fortification, are used to seal roller bearings against grease leakage or dirt and splash water ingress in vehicle axles as well as rollers and wheels for all equipment types, engines in transport technology, motion sequences in construction equipment and agriculture machines.

Ring carrier seals in accordance with design 01 and 02 have spring-loaded, flexible sealing lips. This has advantages if splash water can frequently be expected in the sealing area.

Plastic ring carrier seals are also suitable as a protection seal in front of radial shaft seal arrangements.

Installation

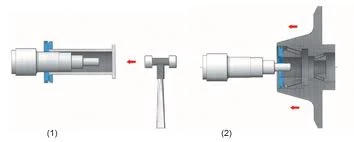

In general, the ring carriers can be moved by hand by lightly tapping with a mallet (1) onto the axle stub. The ring carrier should initially be moved onto the hub (2) if an installation slope is undesired or only a small slope is available. In general, the ring carriers can be moved by hand by lightly tapping with a mallet (1) onto the axle stub. The ring carrier should initially be moved onto the hub (2) if an installation slope is undesired or only a small slope is available.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK8 PLASTIC LAMINAR RING CARRIER SEALS

Design 1 – Ring Carrier with a short sealing lip for symmetrical roller bearings

| Ø D | Ø D1 | S | R | Product No. |

| 47 | 20 | 7.7 | 1 | 472077 R1 |

| 47 | 25 | 7.7 | 2 | 472577 R1 |

| 52 | 25 | 6 | 3 | 52256 R1 |

| 62 | 30 | 7 | 3 | 62307 R1 |

| 72 | 35 | 7 | 3 | 72357 R1 |

FK8 PLASTIC LAMINAR RING CARRIER SEALS

Design 2 – Ring carrier with a long sealing lip for tapered roller bearings

| Ø D | Ø D1 | S | R | Product No. |

| 52 | 25 | 6 | 3 | 52256 K1 |

| 55 | 30 | 7 | 3 | 55307 K1 |

| 62 | 30 | 7 | 3 | 62307 K1 |

| 62 | 35 | 7 | 3 | 62357 K1 |

| 72 | 35 | 7 | 3 | 72357 K1 |

FK8 PLASTIC LAMINAR RING CARRIER SEALS

| Ø D | Ø D1 | S | R | Product No. |

| 80 | 40 | 7 | 3.5 | 80407 |

| 85 | 45 | 7 | 4 | 85457 |

| 90 | 50 | 6 | 3.5 | 90506 |

| 90 | 50 | 7.5 | 4 | 905075 |

| 100 | 55 | 8 | 4 | 100558 |

| 110 | 60 | 8 | 4 | 100608 |

| 120 | 65 | 9 | 4.5 | 120659 |

| 125 | 70 | 10 | 5 | 1257010 |

| 125 | 80 | 10 | 5 | 1258010 |

| 140 | 80 | 9 | 5 | 140809 |

| 150 | 85 | 14 | 6 | 1508514 |

| 150 | 100 | 14 | 6 | 15010014 |

HOW TO SPECIFY LAMINAR SEALING RINGS - FK3 SINGLE WOUND

FEY part numbers are a combination of the series, style, bore/shaft diameter (D), radial section (RB), ring thickness (RD), and ring material.

A special part number is assigned to ring sizes that have special features like coatings or surface finishes.

Series

FK3 –

Style

[AS]

[ASK]

[IS]

[ISK]

Bore/Shaft Ø

D /

Radial Section

RB x

Ring Thickness

RD

The following is an example of a FEY part number:

Style = AS

D = 50

RB = 2.4

RD = 1.45

HOW TO SPECIFY LAMINAR SEALING RINGS - FK3 SINGLE WOUND

FEY part numbers are a combination of the series, style, bore/shaft diameter (D), radial section (RB), ring thickness (RD), and ring material.

A special part number is assigned to ring sizes that have special features like coatings or surface finishes.

| BORE | SHAFT | ||||||||

| Series | Style | Bore/Shaft Ø | Opposing Ø | Set Thickness | Series | Style | Bore/Shaft Ø | Opposing Ø | Set Thickness |

| FK5 – | [AS][ASK][ASD][ASKD] | D / | D-(2*RB) x | [RB*3][RB*5][RB*2][RB*3] | FK5 | [IS][ISK][ISD][ISKD] | D / | D+(2*RB) x | [RB*2][RB*5][RB*2][RB*3] |

Fey LAMINAR RETAINING RINGS

FEY provides both single and double wound retaining rings for a variety of uses where parts need to be fixed axially. This includes construction, agricultural machinery, mechanical engineering, automotive components and aerospace applications. There are several advantages to using FEY Laminar retaining rings. The roundness of the ring over 360° ensures strong contact with the groove bottom and continuous support around the circumference. This allows for the ring to remain reliably retained in the groove, even under high axial load. The ring remains well balanced during rotation and is absolutely free from material defects.

Internal Rings for Bores

Internal retaining rings are used where axial fixing is required in a housing bore. FEY offers type ESB (singe wound) and DSB (double wound) retaining rings.

Special Purpose Rings

FEY offers special purpose rings like style DMS (double wound) with its locking feature designed to resist higher centrifugal forces from shaft speeds that are beyond the range of standard rings. Additional styles are available for high thrust loading and precision component locating.

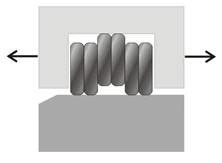

Fey LAMINAR PISTON RINGS

FK2 Laminar piston rings

For pistons of internal combustion engines, compressors, pneumatic and hydraulic equipment and shock absorbers,

The FK2 laminar piston rings are manufactured to work with or without cast iron piston rings.

FK2 piston rings offer many advantages in applications where physical size limits the use of cast iron rings. FEY Laminar Piston Rings are excellent choices for hydraulic and pneumatic piston seals. Laminar piston rings are used to seal shock absorbers.

FK4 Laminar piston rings

For pistons of freeform and drop forging machine, hydraulic controls and presses.

FK 4 laminar piston rings have been designed for the particular requirements of freeform and drop forging machines and presses and hydraulic controls. Ring profiles and features offer optimal performance in these applications.

Fey FK2 LAMINAR PISTON RINGS

Application

Laminar sealing rings “FK2” can be used for previously used and new internal combustion engines in connection with cast iron piston rings. Cast iron piston rings are not required for pistons of hydraulic and pneumatic

equipment, compressors and shock absorbers.

Please contact our technical office for information about ring dimensions, ring materials and groove geometries.

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions exactly for enquiries and/or orders for all ring types.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK4 LAMINAR PISTON RINGS

Application

Laminar sealing rings “FK4” for pistons of freeform and drop forging machines, presses and hydraulic controls.

Please contact our technical office for information about ring dimensions, ring materials and groove geometries.

Freeform/drop forging machine

Presses

Hydraulic control

Ordering Information

The ring diameter information must match the housing or shaft diameter dimensions exactly for enquiries and/or orders for all ring types.

Run and Installation Tests

Run and installation tests under operating conditions must be performed in each case before standard

production of FEY laminar sealing rings can begin to determine whether the desired sealing effects can be achieved.

FK8 PLASTIC LAMINAR RING CARRIER SEALS

Outside sealing plastic ring carrier seal units are used to seal ball and roller bearings against loss of grease and ingress of dirt or splash water. They are made from Polyamide 6.

Plastic ring carrier seals are also used for vehicle axles, other wheels, pulleys, drive systems in vehicles, construction equipment, fire engines, etc.

Some ring carrier seals are equipped with an additional sealing lip which comes in contact with the bearings outer race. This is advantageous where high levels of splash water are encountered.

APPLICATIONS

FEY sealing solutions are currently in service in various industrial applications. The unique functionality of FEY

laminar sealing rings makes it an excellent choice when operating conditions exceed the capabilities of standard lip seals. FEY sealing solutions can be engineered into most existing applications with nominal modifications.

Look to FEY laminar sealing rings when your application has:

- High temperatures

- Low friction requirements

- High level of contaminates

- High operating speeds

APPLICATIONS EXAMPLES

Fey Sealing Rings AXIAL & RADIAL MOVEMENT CONSIDERATIONS

Axial

The groove width A or B must be widened by twice the axial play if play occurs in the area of the rings.

Damage to the rings and the surrounding components may occur if this is not adhered to.

It is recommended to use the full groove width tolerances, especially in cases involving thermal expansion.

Radial

The external clamping rings, the groove diameter D1 must be decreased by the radial play if radial play occurs in the area of the rings.

For internal clamping rings, the groove diameter D2 must be increased by the radial play if radial play occurs in the area of the rings.

Damage to the rings and the surrounding components may occur if this is not adhered to.

Fey Labyrinth Sealing Rings GREASING

General Information for Greasing

Greased laminar rings provide a better seal arrangement than dry running rings, greased laminar rings are required when the application is subject to splash water, dirt and scale. In order to allow sufficient transfer of grease throughout arrangement and prevent over pressure during application, it is recommended that grease application bores and grease relief bores are provided. Where possible the ring carrier should be supplied by 4 off 3 to 5 mm diameter bores equally distributed around the circumference and also into the groove base, this will allow easy application and exchange of grease during re-lubrication.

Greasing options

Listed below are three different and proven greasing options with greasing bores or grease relief bores, which can be arranged depending on the available space. Leakes from the outside are not possible because the bores are filled with grease.

Lubrication recommendation

We cannot make any recommendations for the selection of the lubricant or provide information about the greasing frequency. The type and quantity of an appropriate lubricant must be determined and specified by the customer depending on the operating conditions such as speed, operating temperatures, contamination level and ambient conditions. Bearing and lubricant manufacturers may be able to provide information.

Note

The “FK5-HFL” ring types are the exception with respect to greasing. They must be installed dry and without any additional lubricants. The surrounding components, which come in contact with the laminar rings must also not be greased. The lubricants carbonize due to the high operating temperatures and the laminar rings will fail.

MATERIALS

- Variable depending on the thermal treatment type! Hardness values depending on ring cross section measured in Rockwell HTRA or HRC.

- The surface colour can vary depending on the thermal treatment type: bright, light brown or blackened.

- For FK8 series, depending on the requirements, the listed laminar ring materials are available, please include the laminar ring material in your order.

| Steel Type | Spring Resistant up to | Hardness | Surface Treatment | Surface Protection | Surface Colour | Available for Series |

| C75S-DIN 1.0605 | Max +300oC | On request (1) | – | Oiled | Variable (2) | FK2, FK3, FK4, FK6, FK7, FK8 (3) |

| C60E-DIN 1.1221 | Max +300oC | On request (1) | – | Oiled | Variable (2) | FK2, FK3, FK4, FK6, FK7 |

| 50CrV4-DIN 1.8159 | Max +400oC | On request (1) | – | Oiled | Variable (2) | FK2, FK3, FK4, FK6, FK7 |

| CrNi-DIN 1.4310 | Max +450oC | On request (1) | – | Bright & Dry | Variable (2) | FK3, FK6, FK7, FK8 (3) |

| CrNi-DIN 1.4571 | Max +500oC | On request (1) | Vibratory grinding | Dry | Variable (2) | FK5, FK5-HFL, FK8 (3) |

| CrNi-DIN 1.4980 | Max +700oC | On request (1) | Vibratory grinding | Dry | Variable (2) | FK5-HFL |

FEY Sealing Rings MANUAL INSTALLATION

Manual installation is the most widely used form for installation of the FEY sealing rings. Because these components are precision engineered and manufactured, care must be taken during installation not to damage the rings. The following points will guide you to smooth installation by hand.

Ring Gap Orientation

The ring gaps should be oriented so a leak path is not created from one ring to the next. In pairs, ring gaps should be oriented approximately180° apart. For sets of three, ring gaps should be approximately120° apart. In sets of four, adjacent ring gaps should be at least 90° apart.

Axial Spreading

Single and double wound rings are manually installed into the grooves by axially spreading the rings at the ring ends. Care must be taken to ensure the rings are not overstretched. If rings are overstretched, they will become permanently deformed. Rings should not be spread radially during installation.

On Shaft

Start by spreading the ring axially (see Axial Spreading section above).

Insert the ring end into the groove .

Rotate the ring into the groove until it is completely installed.

Check to make sure ring gaps are oriented properly.

In Bore

Start by spreading the ring axially (see Axial Spreading section above). Insert the ring end into the groove. Rotate the ring into the groove until it is completely installed. Check to make sure ring gaps are oriented properly.

Ring Overlap

During installation of the single and double wound rings, care must be taken not to spiral the ring ends into adjacent rings that are already installed. Also, during installation of the double wound rings, care must be taken not to reverse the location of the ring end in relation to the bend at the gap.

Special 'IS' Ring Considerations

The installation of IS ring into dual grooves is only possible when housing grooves are accessible from both sides.

Spiraling IS rings with increased cross sections (RB) into housing bores is not possible. They must be installed into a groove formed by an end plate or a DSB retaining ring.

Retaining Ring Disassembly

Disassembly of the retaining rings is easily accomplished with the aid of a flat bladed screwdriver. Insert the blade of the screwdriver into the disassembly notch at the ring end and rotate until it is removed from the groove. Continue to spiral the rest of the ring out of the groove. Please verify all dimensions are within manufacturing specifications prior to reusing a retaining ring.

TOLERANCES

|

Single Wound Laminar Sealing Rings |

|||||

|

FK 3/FK 5 |

Bore/Shaft Dimensions (mm) |

Tolerances |

|||

|

ISO Shaft |

ISO Bore |

RB |

RB |

||

|

15 – 104-9 |

h6 – h7 |

H6 – H7 |

+0.1 / -0.1 |

+0.04 / -0.02 |

|

|

105 – 149.9 |

h7 – h8 |

H7 – H8 |

+0.1 / – 0.2 |

+0.05 / -0.03 |

|

|

150 – 439.9 |

h8 – h9 |

H8 – H9 |

+0.15 / -0.3 |

+0.06 / -0.04 |

|

|

440 – 1300 |

h9 – h10 |

H9 – H10 |

+0.2 / -0.4 |

+0.07 / -0.05 |

|

|

Double Wound Laminar Sealing Rings |

|||||

|

FK 6/FK 5 |

Bore/Shaft Dimensions (mm) |

Tolerances |

|||

|

ISO Shaft |

ISO Bore |

RB |

RB |

||

|

15 – 104.9 |

h6 – h7 |

H6 – H7 |

+0.1 / -0.1 |

+0.08 / -0.04 |

|

|

105 – 149.9 |

h7 – h8 |

H7 – H8 |

+0.1 / – 0.2 |

+0.01 / -0.06 |

|

|

150 – 439.9 |

h8 – h9 |

H8 – H9 |

+0.15 / -0.3 |

+0.012 / -0.08 |

|

|

440 – 1300 |

h9 – h10 |

H9 – H10 |

+0.2 / -0.4 |

+0.014 / -0.01 |

|

Related Laminar Seal Rings Products

Bearings

Fuji Bearing Lock Nuts