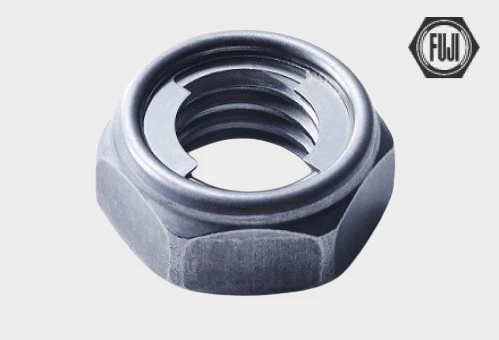

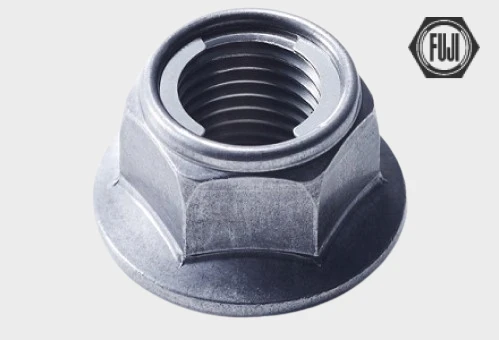

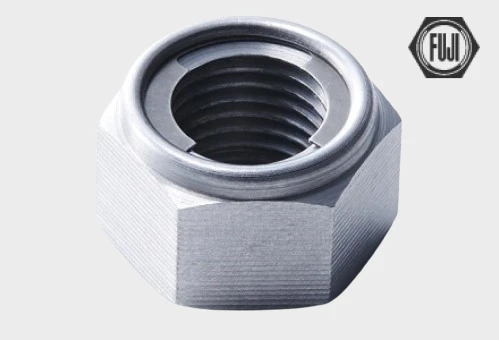

FUJILOK U-nut

Features

- Fastening function: Demonstrates stable locking function

- Dropout prevention: Prevents premature detachment even if the tightening force is lowered

- Reusability: Fuji bearing lock nuts U-nut may be re-used with very little prevailing torque decline.

- Simple fastening: Easy tightening with no need for skilled techniques or specialized tools

- Simplex parts: It demonstrates a locking effect by itself, making parts management easy and preventing installation errors

- Heat and cold resistance: An all-metal product with excellent resistant to heat and cold

Applicable Markets

- Two-wheeled vehicles

- Marine vessels

- Four-wheeled vehicles

- Electronics

- Plants

- Infrastructure

- Special-equipped vehicles

- Playground equipment

- Machine tools

- Civil engineering

- Farm equipment

- Railways

- Industrial equipment

- Architecture

- Conveyers

- Medical care and welfare

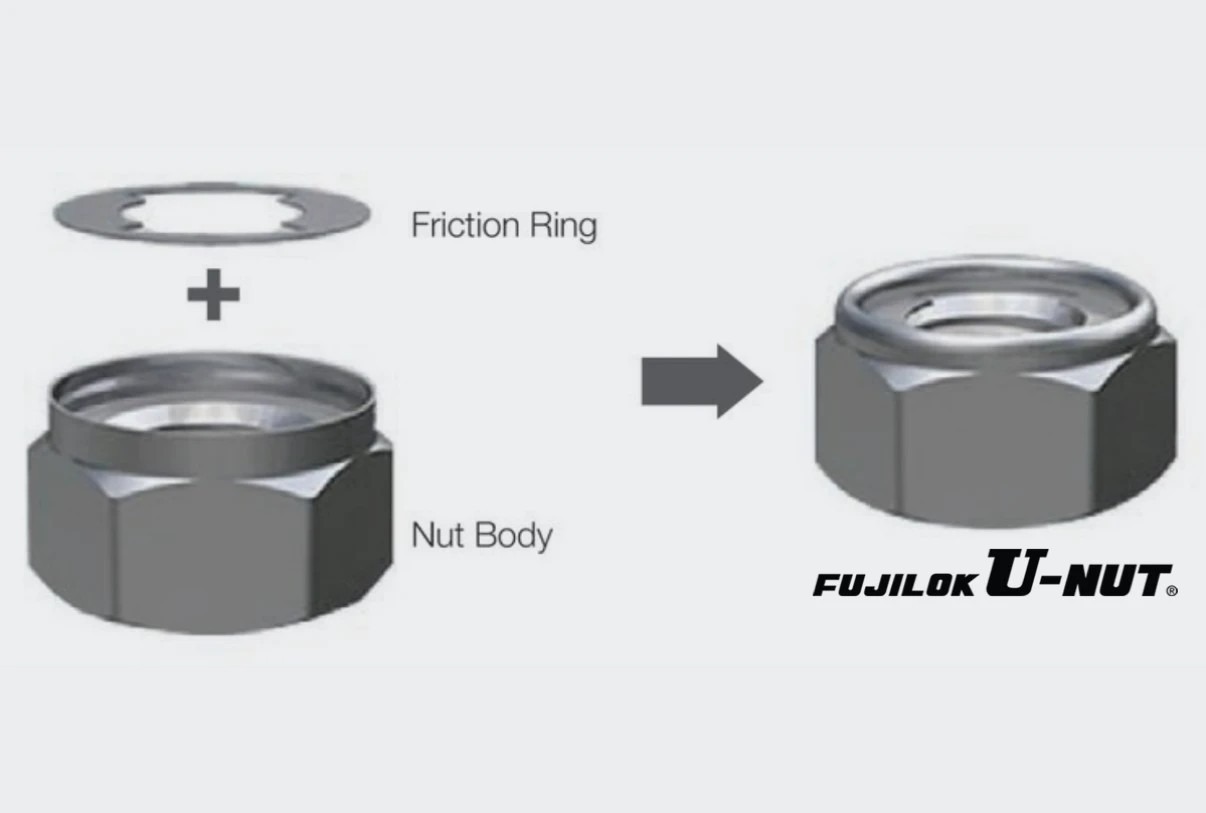

- Consists of 3 basic parts

- No need for a lock washer

Structure & Function

The FUJILOK U-NUT consists of a nut and friction ring (specialized ring).The friction ring is secured to and integrated with the top face of the nut by crimping.

| Steel friction ring | 60° 3-wing ring (up to M6) 90° 2-wing ring (M8 and above) |

|---|---|

| Thread accuracy | JIS6H(JIS Class2),formerly JIS Class2, JIS2B |

| Sizes | M3 – M115 *Pitch: Coarse thread and fine thread W3/16-24 – W2″-4.5 NC#10-24 – NC1″1/2-6 NF#10-32 – NF1″1/2-12 *Other special sizes |

| Shapes | FUJILOK U-NUT Single Chamfer(Type 1), Double Chamfer (Type 2), Thin Type (Type 3), Small Type U-NUT, Flange Type U-NUT, Cap Type U-NUT, Weld Type U-NUT. |

| Materials | SS400 or equivalent, S45C thermal refined or equivalent, SUS304 or equivalent, SCM435 (thermal refined), titanium, SUS316L, brass (BSBM) *Other special materials |

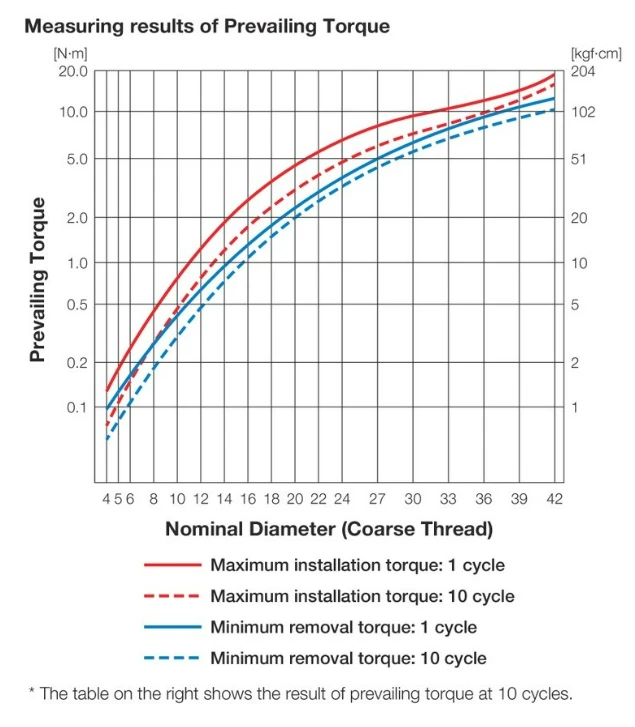

Performance of the prevailing torque and reusability

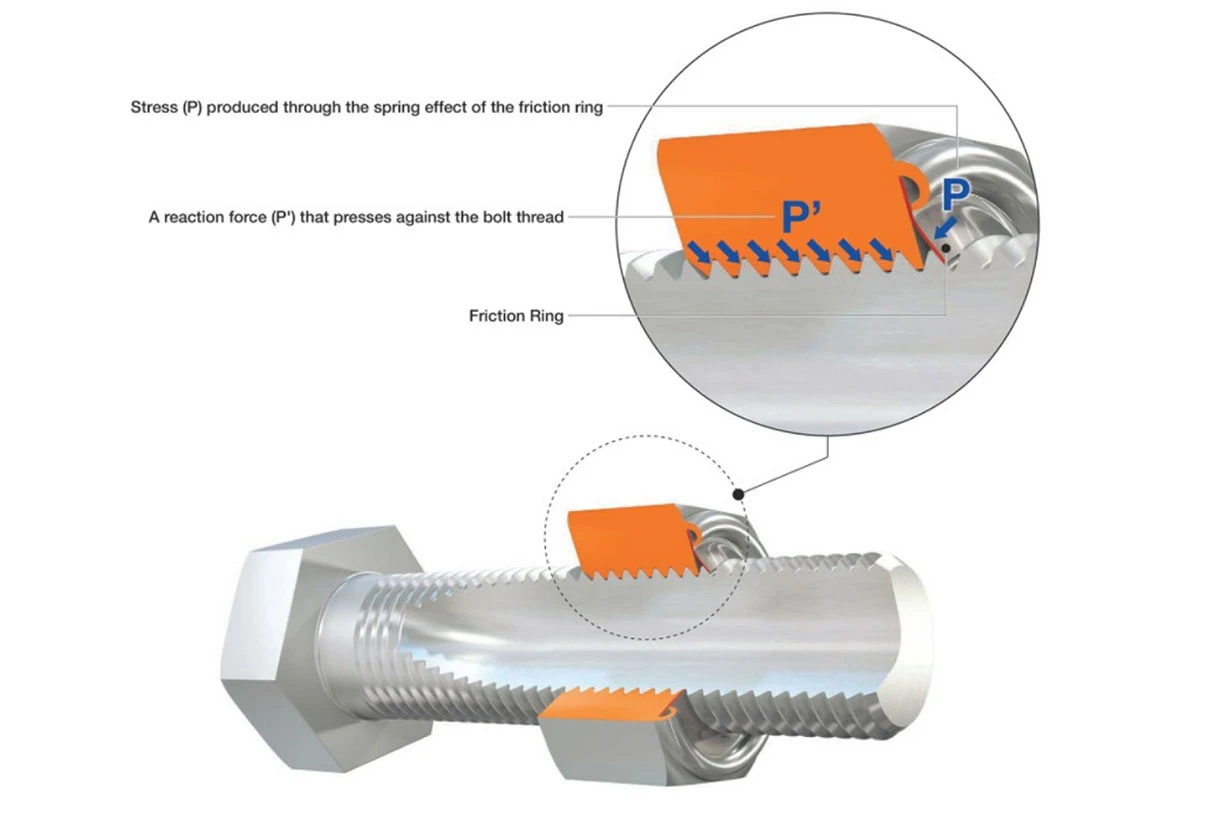

Prevailing torque is produced by the spring effect when the friction ring touches the bolt threads.

Sample

| M12 × 1.75 SS400 equivalent non-plating | |||

|---|---|---|---|

| Maximum Installation torque | Minimum removal torque | ||

| 1cycle | 10cycle | 1cycle | 10cycle |

| 1.20 | 0.75 | 0.70 | 0.50 |

[N・m]

*Via in-house testing

Even re-used 10 times, the prevailing torque shows only a slight decrease.

Test Condition

| Bolt material | Alloy steel (SCM435) |

|---|---|

| Thread accuracy | ISO6g (JIS6g) |

| Surface treatment | plain (nut and bolt) |

| Lubricant | penetrating lubricant |

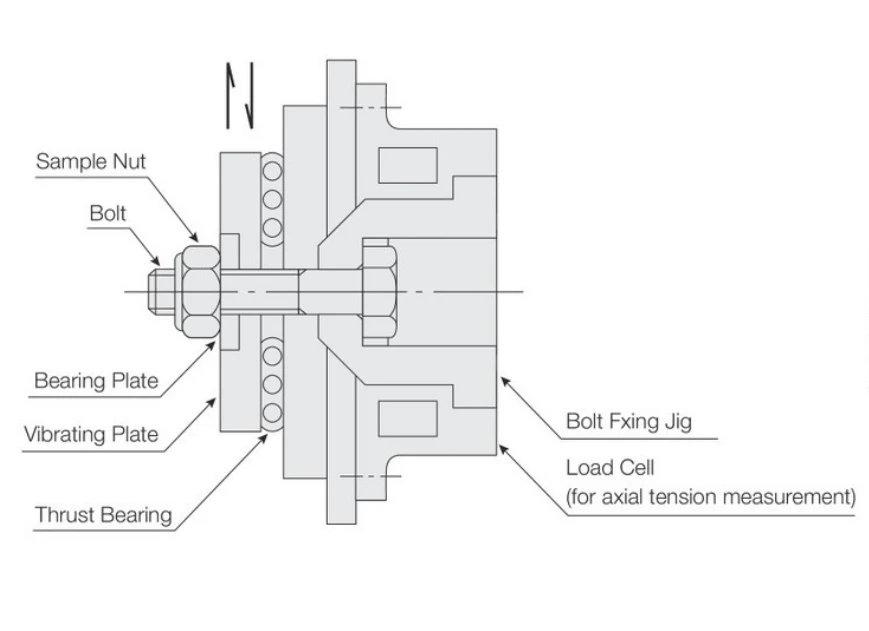

This test repeatedly applies amplitude and impact in a direction vertical to the axis of the bolts and nuts that are assembled in a vibration plate in order to examine the reduced axial tension of the fastener and judge the locking performance.

Test Condition

| Sample size | M12×1.75 |

|---|---|

| Material of the sample nut, bolt | SS400 or equivalent |

| Axial tension for fastening | 17,150N{1,750kgf} |

Specification of the Junker Type Thread Loosening Testing Machine

| Frequency | 1,278c.p.m. |

|---|---|

| Excitation stroke | 11mm |

| Impact stroke | 10mm |

| Vibration acceleration of the excitation table | 10G |

| Excitation time | 60 min. |

| Direction of impact | Bolt axial direction |

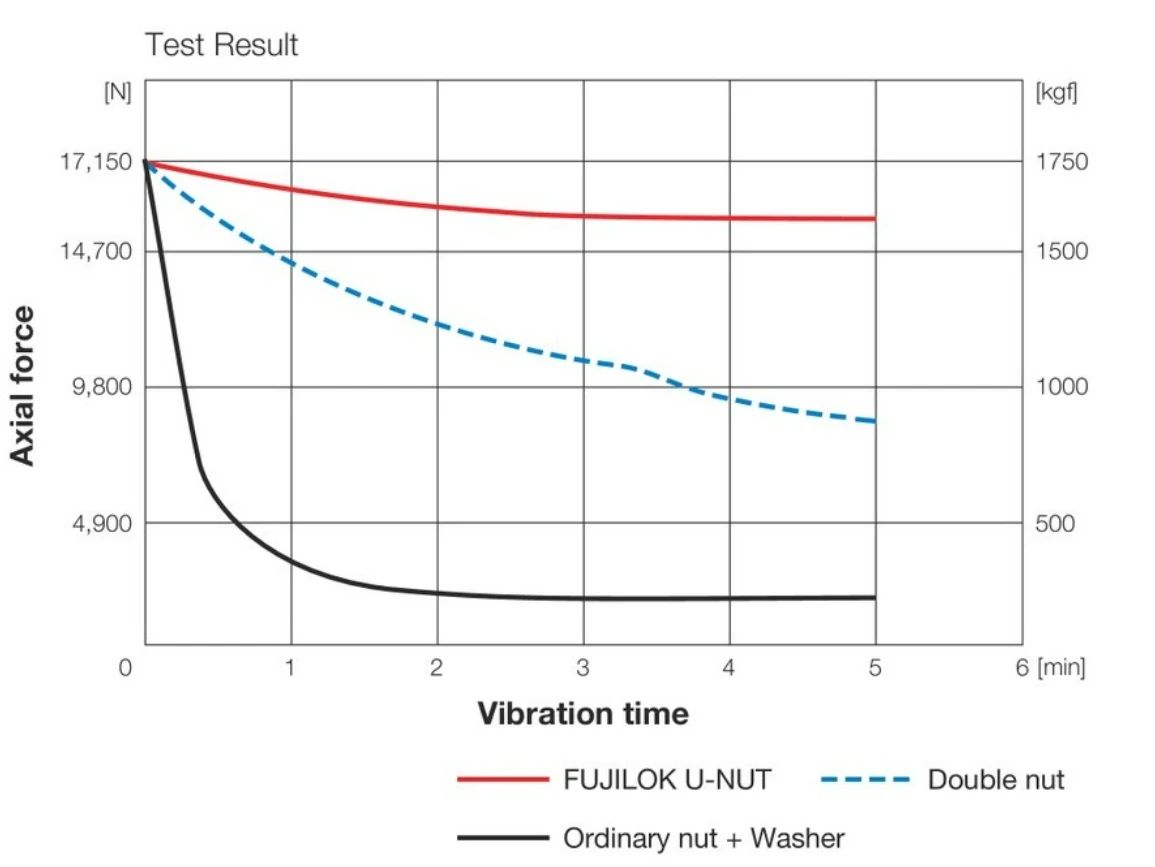

Test Result

Vertical Axis Vibration Test video

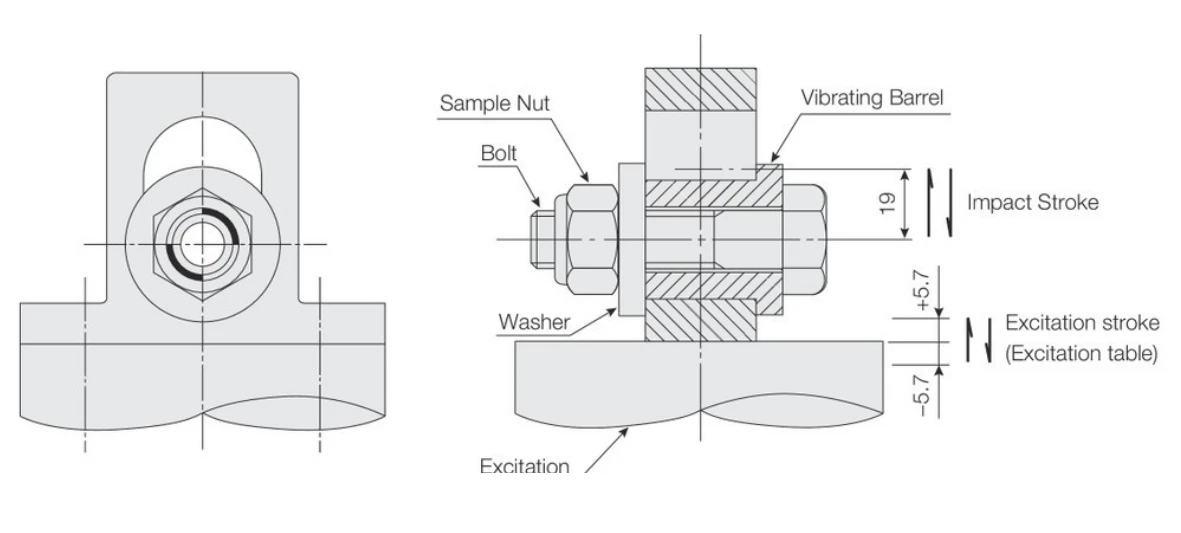

NAS Conforming High Speed Thread Looseness Test (according to National Aerospace Standard NAS3350)

This test repeatedly applies shocks in a direction vertical to the axis of the bolts and nuts that are assembled a vibration barrel in order to examine whether or not loosening occurs and judge the locking performance.

Test Condition

| Sample size | M12×1.75 |

|---|---|

| Material of the sample nut, bolt | SS400 or equivalent |

| Axial tension for fastening | 17,150N{1,750kgf} |

Yield point of Bolt σy:314N/mm²{32kgf/mm²}

Specification of NAS Conforming High Speed Thread Loosening Testing Machine

| Frequency | 1,780 c.p.m. |

|---|---|

| Excitation stroke | 11mm |

| Impact stroke | 19mm |

| Vibration acceleration of the excitation table | 19.5G |

Test Result

| Sample size | Frequency | Vibration time |

|---|---|---|

| FUJILOK U-NUT | 30,000cycles | 16′ 51″ |

| No problem | ||

| Double nut | 4,450cycles | 2′ 30″ |

| Failed | ||

| Ordinary nut + Washer | 1,335cycles | 45 sec. |

| Failed | ||

Vertical Axis Vibration Impact Test video

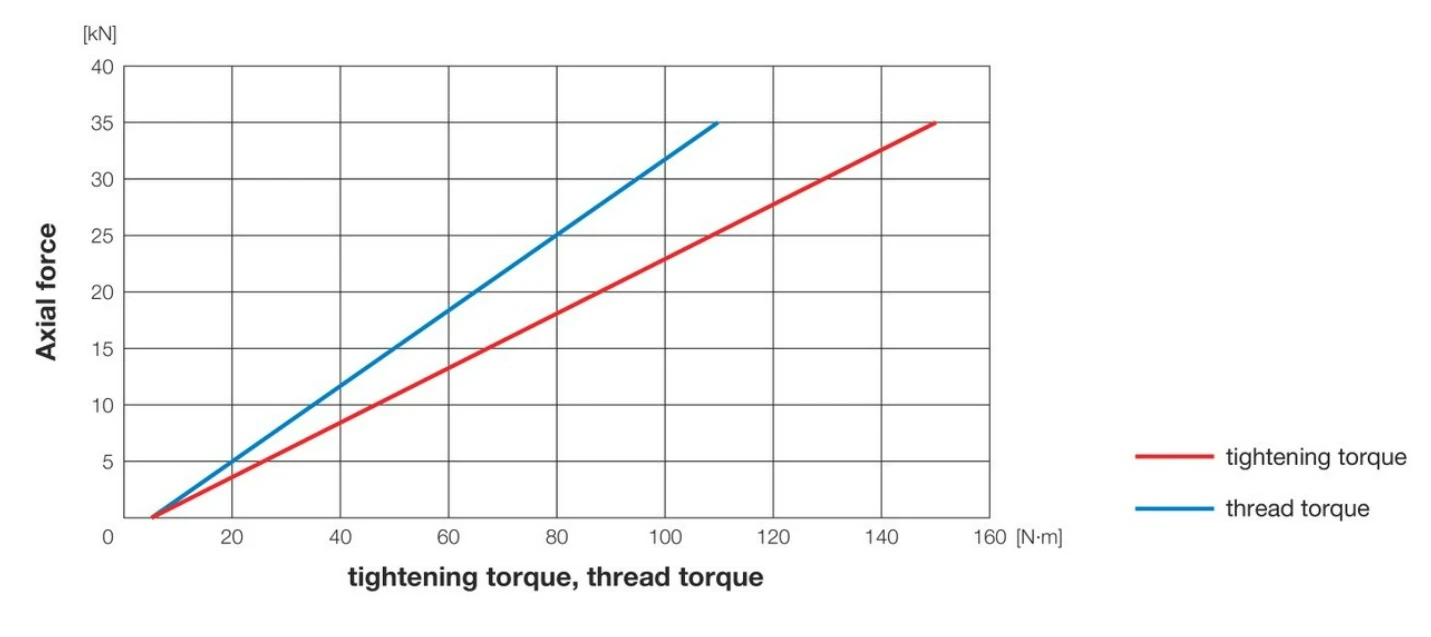

Test Result

Threaded Fastener Tightening Characteristic Test video

Installation Instructions

1

2

3

4

1

2

3

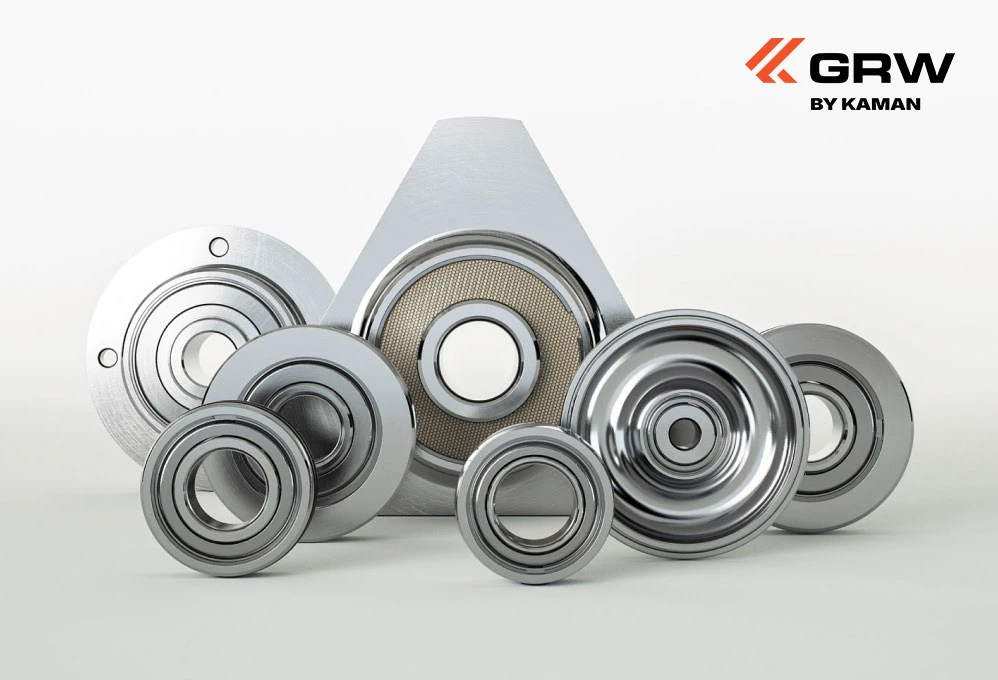

Explore our product range

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.