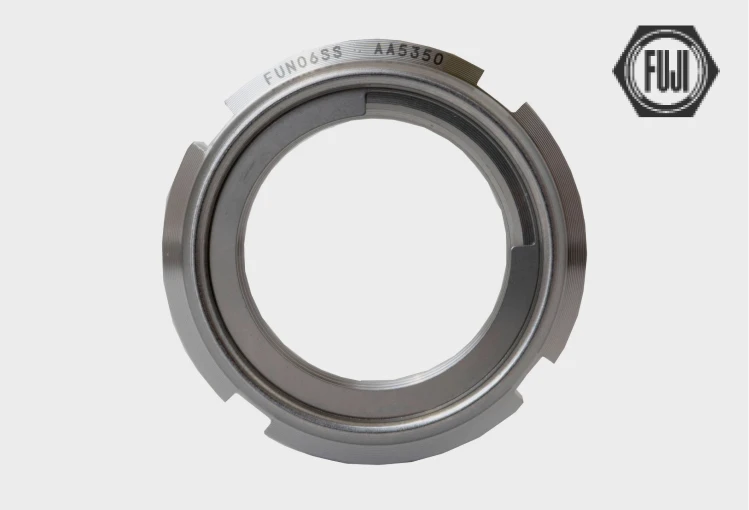

FUJI Fine U-Nuts

Features

- Reusability: Fuji bearing lock nuts may be re-used with very little prevailing torque decline.

- Simple fastening: Fine adjustment is possible from any position, and torque management is easy.

- Simple and time-saving installation : Eliminates the need for toothed lock washers and the keyway machining of shafts.

- Balance: Improves rotational balance of the shaft.

- Weight reduction: Allows for the use of hollow shafts that are thinner than normal.

- Cost reduction: Achieves a total cost reduction by eliminating the need for processing, parts, and technology that were previously required

- Dedicated tools in a range of sizes, from M10 to M100, are available

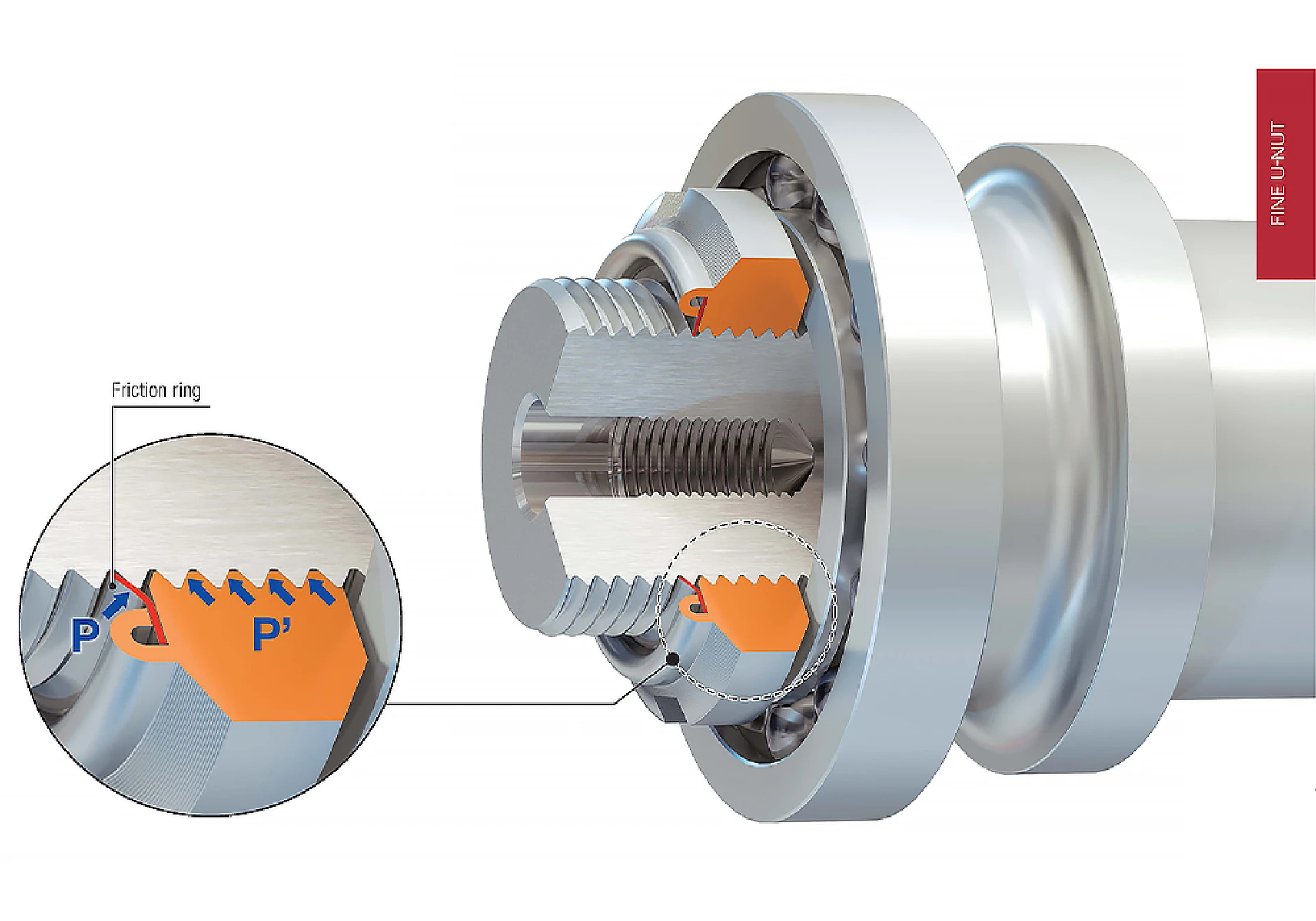

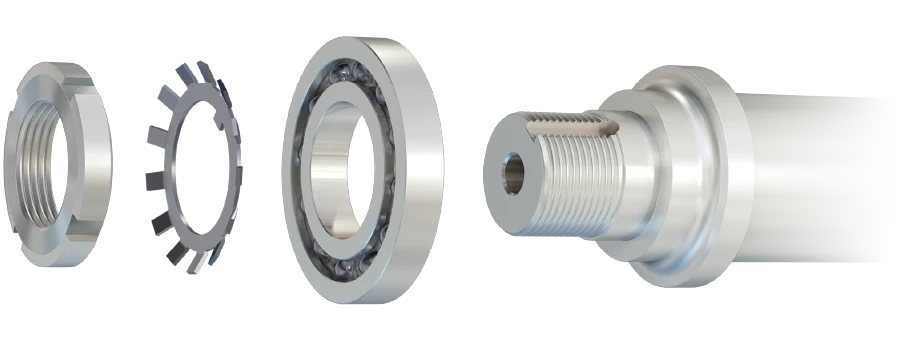

Structure & Function

When “FINE U-NUT” is screwed onto a shaft, the friction ring comes into contact with the shaft thread. As the nut is tightened further, the friction ring begins to bend along with the screw thread and presses against the shaft screw threads.A spring effect produced by the friction ring (P), along with a reactionary force that pushes against the screw flank surface (P’), generates prevailing torque (frictional torque) and demonstrates the locking function.

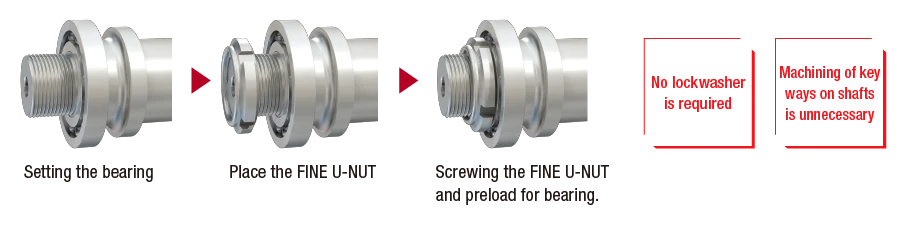

The FINE U-NUT vs. Conventional Product

- Consists of 3 basic parts

- No need for a lock washer

- Just insert to fasten

- No need to for specialist machining of keyways into shaft

Conventional Product

- Consists of 4 basic parts.

- A toothed lock washer and keyway machining are required.

| Steel friction ring | 270°ring |

|---|---|

| Thread accuracy | JIS6H (JIS Class 2) Face runout (maximum): 0.05 mm (M8 to M50) Face runout (maximum): 0.07 mm (M55 to M120) Face runout (maximum): 0.10 mm (M125 to M150) |

| Sizes | M 8 to M100 (SS Series) M10 to M150 (SC Series) M10 to M100 (SUS Series) *Pitch: Fine thread |

| Shapes | Grooved round nut *Other special shapes |

| Materials | SS400 or equivalent, S45C (thermal refined), SUS304 or equivalent |

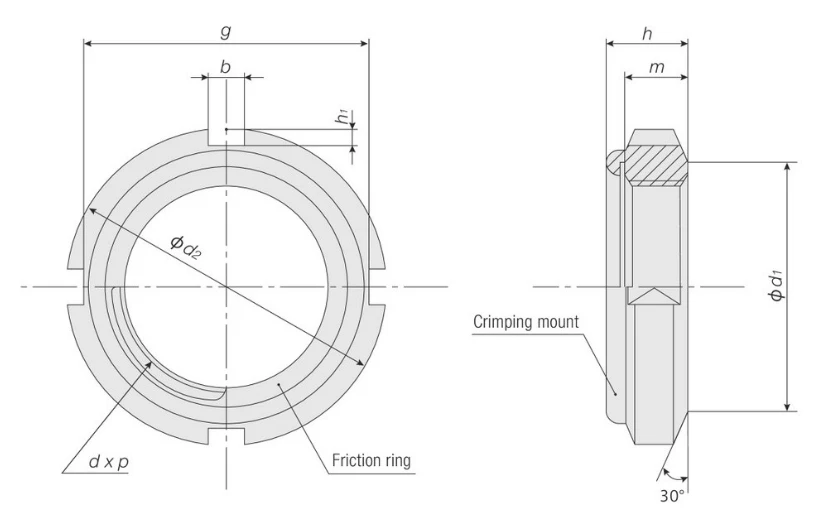

| Part No. | Designation of Thread (d×p) | Flange Diameter (φd1) | Outside Diameter (φd2) | Overall Height (h) | Thread Height (m) Approx. | Width of locknut slot (b) | Depth of locknut slot (h1) Approx. | Locknut slot opposite side (g) | Maximum face runout (max) | Thread accuracy length ℓmin | Unit Weight (g) Approx. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SC Series (S45C-H) | SS Series (SS400) | SUS Series (SUS304) | ||||||||||||||||

| ― | FUNM8SS | ― | M 8×0.75 | 12.0 | 0 -0.5 | 16 | 0 -0.5 | 5.3 | ±0.3 | 4.3 | 3 | ±0.2 | 1.5 | 13.0 | 0 -0.5 | 0.05 | 5.8 | 4.1 |

| FUN00SC | FUN00SS | FUN00SUS | M10×0.75 | 13.5 | 18 | 5.2 | 4.0 | 3 | 1.8 | 14.4 | 5.5 | 4.5 | ||||||

| FUN01SC | FUN01SS | FUN01SUS | M12×1 | 17.0 | 22 | 5.4 | 4.0 | 3 | 1.8 | 18.4 | 6.0 | 8.0 | ||||||

| FUN02SC | FUN02SS | FUN02SUS | M15×1 | 21.0 | 25 | 6.5 | ±0.5 | 5.0 | 4 | 1.8 | 21.4 | 7.0 | 12.0 | |||||

| FUN03SC | FUN03SS | FUN03SUS | M17×1 | 24.0 | 28 | 6.4 | 5.0 | 4 | 1.9 | 24.2 | 7.0 | 13.0 | ||||||

| FUN04SC | FUN04SS | FUN04SUS | M20×1 | 26.0 | 32 | 7.7 | 6.0 | 4 | 1.8 | 28.4 | 8.0 | 23.0 | ||||||

| FUN05SC | FUN05SS | FUN05SUS | M25×1.5 | 32.0 | 38 | 9.1 | 7.0 | 5 | 2.0 | 34.0 | 10.0 | 36.0 | ||||||

| FUN06SC | FUN06SS | FUN06SUS | M30×1.5 | 38.0 | 45 | 9.1 | ±0.8 | 7.0 | 5 | 2.0 | 41.0 | 10.0 | 45.0 | |||||

| FUN07SC | FUN07SS | FUN07SUS | M35×1.5 | 44.0 | 52 | 10.2 | 8.0 | 5 | 2.0 | 48.0 | 11.0 | 70.0 | ||||||

| FUN08SC | FUN08SS | FUN08SUS | M40×1.5 | 50.0 | 58 | 11.2 | 9.0 | 6 | 2.5 | 53.0 | 12.0 | 95.0 | ||||||

| FUN09SC | FUN09SS | FUN09SUS | M45×1.5 | 56.0 | 65 | 12.5 | ±1.0 | 10.0 | 6 | 2.5 | 60.0 | 13.0 | 130.0 | |||||

| FUN10SC | FUN10SS | FUN10SUS | M50×1.5 | 61.0 | 70 | 13.5 | 11.0 | 6 | 2.5 | 65.0 | 14.0 | 160.0 | ||||||

| FUN11SC | FUN11SS | FUN11SUS | M55×2 | 67.0 | 75 | 13.5 | 11.0 | 7 | 3.0 | 69.0 | 0.07 | 15.0 | 185.0 | |||||

| FUN12SC | FUN12SS | FUN12SUS | M60×2 | 73.0 | 80 | 13.5 | 11.0 | 7 | 3.0 | 74.0 | 15.0 | 190.0 | ||||||

| FUN13SC | FUN13SS | FUN13SUS | M65×2 | 79.0 | 85 | 15.0 | ±1.5 | 12.0 | 7 | 3.0 | 79.0 | 16.0 | 235.0 | |||||

| FUN14SC | FUN14SS | FUN14SUS | M70×2 | 85.0 | 92 | 15.0 | 12.0 | 8 | 3.5 | 85.0 | 16.0 | 265.0 | ||||||

| FUN15SC | FUN15SS | FUN15SUS | M75×2 | 90.0 | 98 | 15.8 | 13.0 | 8 | 3.5 | 91.0 | 17.0 | 320.0 | ||||||

| FUN16SC | FUN16SS | FUN16SUS | M80×2 | 95.0 | 105 | 18.6 | 15.0 | 8 | 3.5 | 98.0 | 19.0 | 430.0 | ||||||

| FUN17SC | FUN17SS | FUN17SUS | M85×2 | 102.0 | 0 -0.75 | 110 | 19.2 | 16.0 | 8 | ±0.3 | 3.5 | 103.0 | 20.0 | 495.0 | ||||

| FUN18SC | FUN18SS | FUN18SUS | M90×2 | 108.0 | 120 | 20.3 | 16.0 | 10 | 4.0 | 112.0 | 20.0 | 630.0 | ||||||

| FUN19SC | FUN19SS | FUN19SUS | M95×2 | 113.0 | 125 | 21.3 | 17.0 | 10 | 4.0 | 117.0 | 21.0 | 725.0 | ||||||

| FUN20SC | FUN20SS | FUN20SUS | M100×2 | 120.0 | 130 | 22.3 | 18 | 10 | 4.0 | 122.0 | 22.0 | 770.0 | ||||||

| FUN21SC | ― | ― | M105×2 | 126.0 | 140 | 22.3 | 18.0 | 12 | 5.0 | 130.0 | 22.0 | 904.0 | ||||||

| FUN22SC | ― | ― | M110×2 | 133.0 | 145 | 23.3 | 19.0 | 12 | 5.0 | 135.0 | 23.0 | 954.0 | ||||||

| FUN23SC | ― | ― | M115×2 | 137.0 | 150 | 23.3 | 19.0 | 12 | 5.0 | 140.0 | 23.0 | 1,030.0 | ||||||

| FUN24SC | ― | ― | M120×2 | 138.0 | 155 | 24.3 | 20.0 | 12 | 5.0 | 145.0 | 24.0 | 1,080.0 | ||||||

| FUN25SC | ― | ― | M125×2 | 148.0 | 160 | 25.4 | 21.0 | 12 | 5.0 | 150.0 | 0.1 | 25.0 | 1,170.0 | |||||

| FUN26SC | ― | ― | M130×2 | 149.0 | 165 | 25.4 | ±2.0 | 21.0 | 12 | 5.0 | 155.0 | 25.0 | 1,250.0 | |||||

| FUN27SC | ― | ― | M135×2 | 160.0 | 175 | 26.6 | 22.0 | 14 | 6.0 | 163.0 | 26.0 | 1,586.0 | ||||||

| FUN28SC | ― | ― | M140×2 | 160.0 | 180 | 26.6 | 22.0 | 14 | 6.0 | 168.0 | 26.0 | 1,748.0 | ||||||

| FUN29SC | ― | ― | M145×2 | 171.0 | 190 | 28.6 | 24.0 | 14 | 6.0 | 178.0 | 28.0 | 2,000.0 | ||||||

| FUN30SC | ― | ― | M150×2 | 171.0 | 195 | 28.3 | 24.0 | 14 | 6.0 | 183.0 | 28.0 | 2,050.0 | ||||||

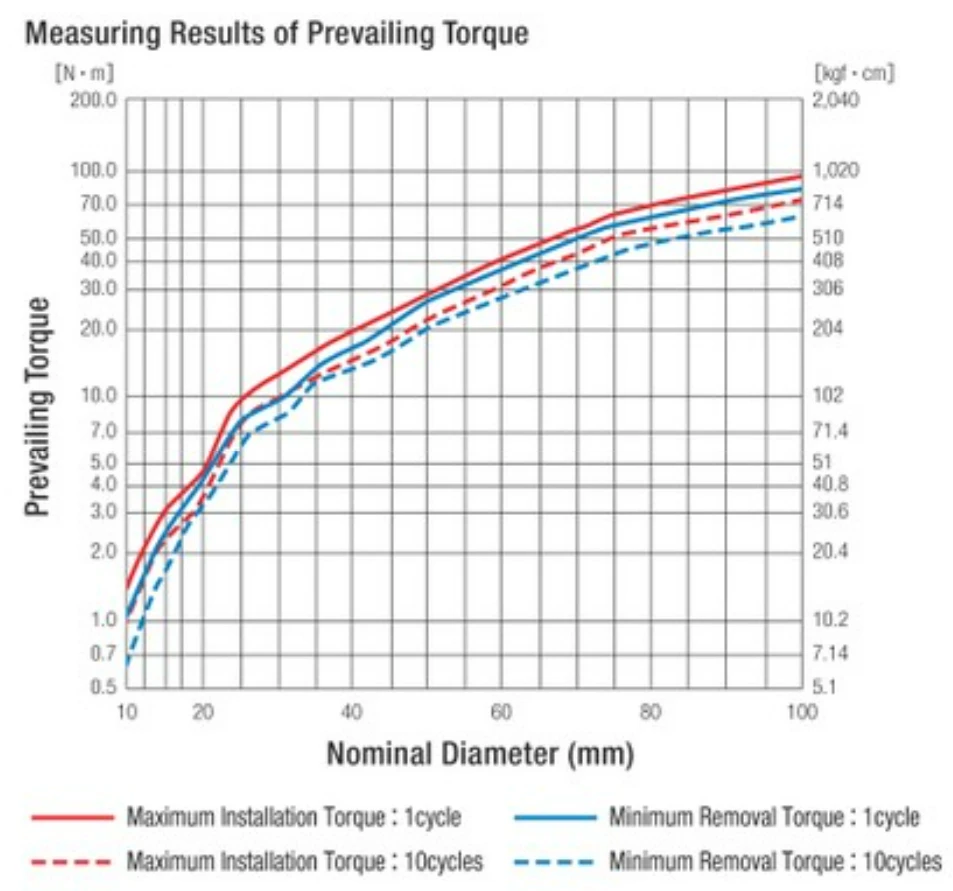

Performance of the prevailing torque and reusability

Prevailing torque is produced by the spring effect when the friction ring touches the bolt threads.

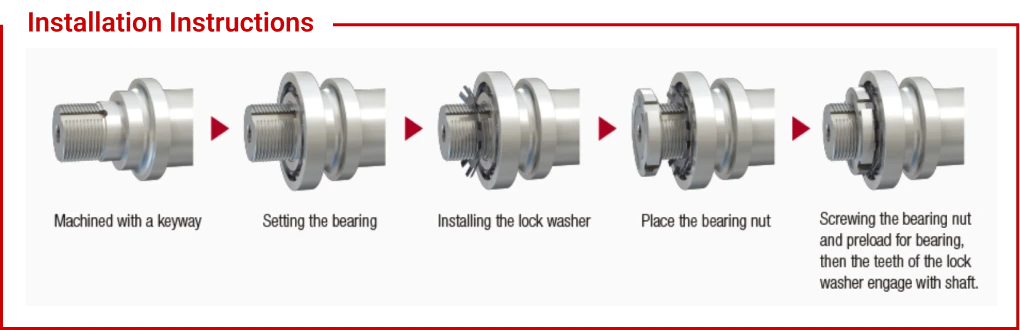

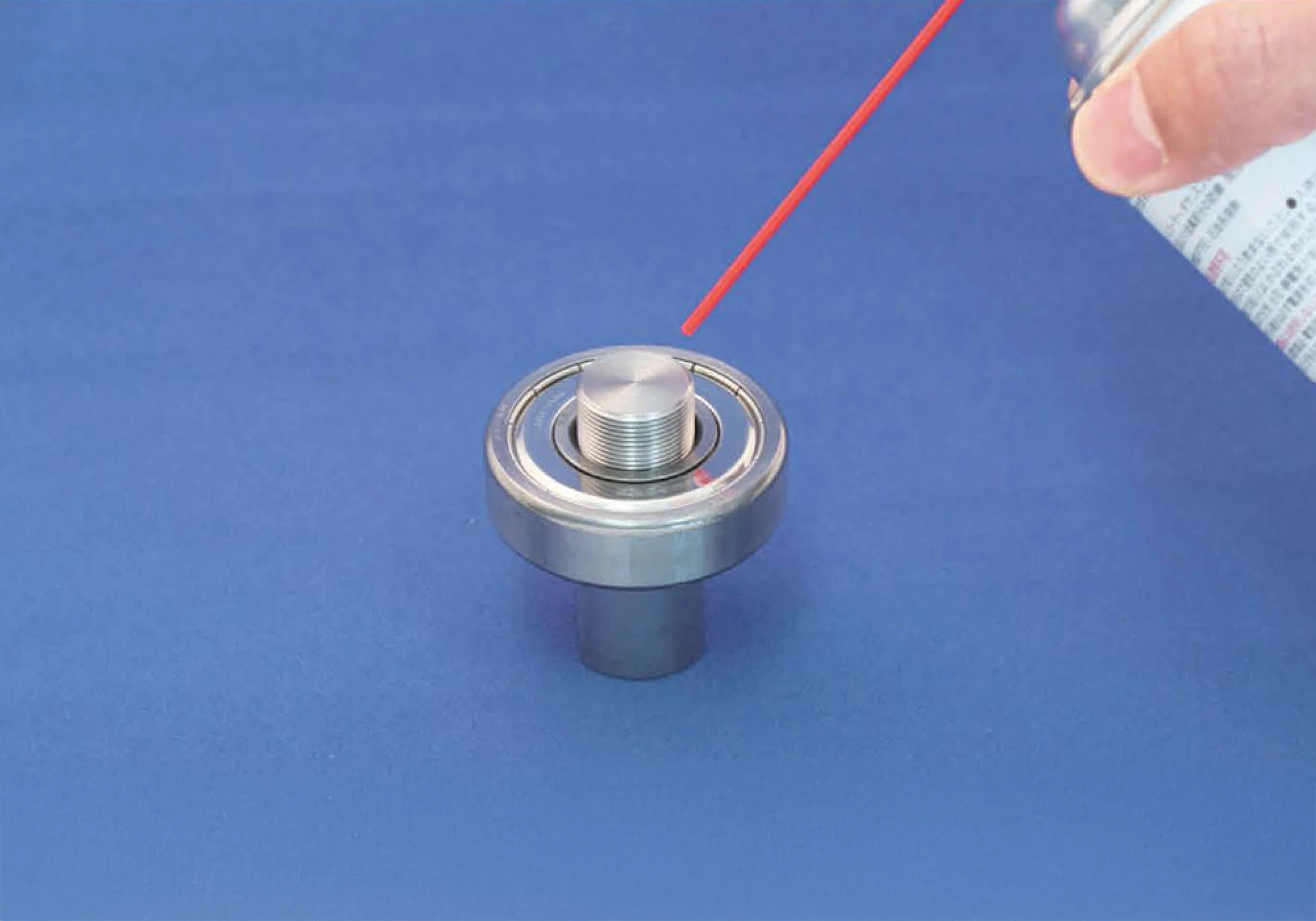

Installation Instructions

1

2

3

4

5

6

*A hook wrench can also used to remove the nut.

Explore our product range

Download our free technical documents and brochures.

Keep up to date with the latest product and technical information from IEC and its international supply partners.