IEC and Schnorr, an exclusive partnership for the UK

At IEC, we take pride in our longstanding partnership with Schnorr, a world leader in disc spring technology. Since the 1960s, IEC has been the exclusive UK partner for Schnorr, combining decades of engineering expertise to deliver high-quality, reliable solutions that help our customers succeed.

IEC has been the Schnorr UK office since the 1960s

Evolution and Advantages of Schnorr

Founded over a century ago, Schnorr has built a reputation as a pioneer in disc spring technology. Their dedication to quality and continuous innovation has made them a trusted name in industries across the globe. Schnorr’s products are engineered to provide superior performance in a compact design, making them ideal for applications where space is at a premium.

Benefits of Schnorr:

- Efficiency: Compact design that delivers high force in small spaces.

- Vibration Resistance: Designed to prevent loosening caused by vibrations, ensuring reliable operation.

- Uniform Load Distribution: Disc spring stacks distribute load evenly, improving system stability and performance.

Your Trusted UK Source for Schnorr Products at the Best Possible Price!

As Schnorr’s exclusive UK distributor, IEC is your go-to source for genuine, high-performance components at the best possible prices. Our partnership with Schnorr means that you benefit from unmatched expertise, product availability, and a commitment to delivering the best value for your projects.

From aerospace to defence, automation to space exploration, IEC and Schnorr components are integral to mission success. In fact, our disc springs were a key part of NASA’s Dragonfly mission to land on Titan, Saturn’s largest moon. When you work with IEC and Schnorr, you’re choosing a partnership that’s built on trust, quality, and a shared commitment to pushing the boundaries of innovation.

Get in touch with us today to discuss how we can meet your component needs, and learn more about our competitive pricing and fast delivery from stock.

Schnorr Disc Springs Applications

- Aerospace, aerostructures, flight control, and actuation

- Automotive and industrial

- Marine and maritime

- Rail and transport

- Green energy and power generation

Schnorr Safety Washers Applications

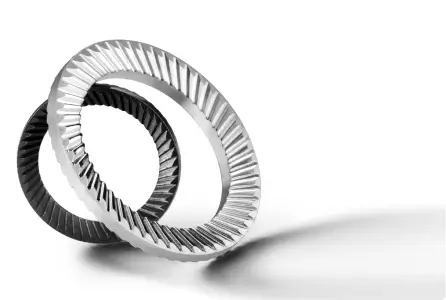

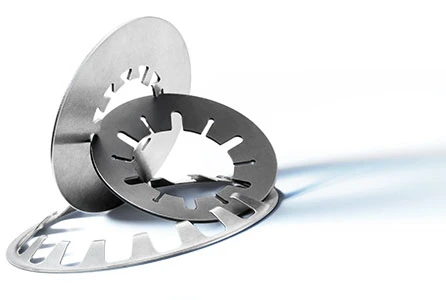

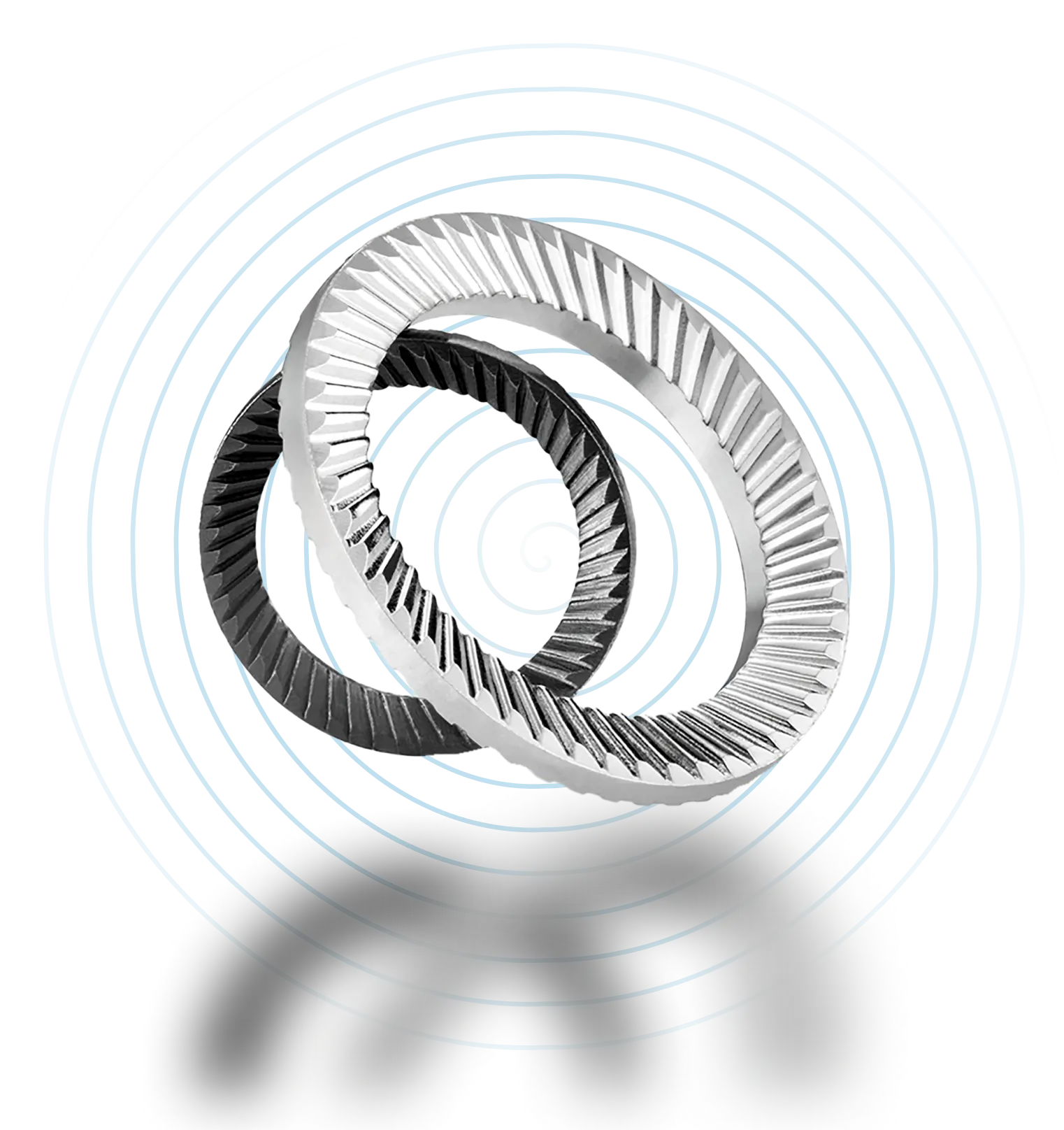

The original SCHNORR® safety washers were developed as a reliable and economic bolt locking device with the basic principle of a disc spring. This ingenious form combines the advantage of security through friction and mechanical locking.

Original SCHNORR® safety washers are now used worldwide where secure fastening connections to counter the effect of vibration are required.

Functional Principle

SCHNORR® safety washers are in the form of a disc spring but with a trapezoidal cross-section and serrations on both sides. The outer diameter is matched to the head diameter of the pan head and socket head cap screws.

Schnorr Disc Springs Features

Original SCHNORR® Disc Springs

The characteristic benefits of original Schnorr® disc springs include:

- Load deflection curves of straight, progressive or degressive character according to the selection of spring arrangement and dimension.

- Simple adjustment of the spring stack length by the addition or removal of individual springs, thus altering the spring stack characteristic.

- Efficient use of space with high spring forces obtainable with small deflections.

- Largely self-damping, particularly with parallel stacking.

- No setting or fatigue under normal loads load.

- Long service life

- Flexibility in applying the disc springs can reduce stock levels.

By means of these characteristics, the original SCHNORR® disc spring has developed such a wealth of application areas that nowadays there is scarcely an engineering area where it is not used.

Schnorr Safety Washers Features

The Original SCHNORR® Safety Washers offer the following advantages.

- High resistance to vibration due to positive locking of the serrations.

- Concentrical force transmission and uniform axial load eliminate bending torques and deformation of the bolt stem.

- The design of the serrations prevents friction and damage to components when tightening.

- Extremely high safety against loss of pretension force and loosening.

- Wide variety of materials and different finishes.

- The closed ring form results in a high degree of pretensioning, while avoiding burst-open effect.

- Development and design of the washers take place based on the screw geometrics, tightening torque as well as the constructive circumstances.

- Also applicable for clearance holes (safety washer is necessary on both sides)

- Applicable for elongated holes (using type VS)

- Equivalent locking effect like wedge-locking washers (according to vibration test DIN 65101 resp. DIN 25201-4 Part B)

Our Exclusive Schnorr Products

Disc Springs

Support a multitude of dynamic processes in an efficient way – often under extreme force and load.

Load Washers

Safety Washers

Wave Springs

Bearing Preload Springs Type 'K'

A specialist slotted geometry bearing spring with a smaller flank and easier initial deflection to meet the precise requirements of ball bearing preload.